Detonation rocket engine: tests, operating principle, advantages

The conquest of outer space involuntarilyis associated with space ships. The heart of any carrier rocket is its engine. He must develop the first space velocity - about 7.9 km / s, to deliver astronauts into orbit, and the second space to overcome the gravitational field of the planet.

New opportunities

Why do they put the detonation enginesbig hopes? According to scientists, their capacity will be 10 thousand times more than the capacity of existing rocket engines. At the same time, they will consume much less fuel, and their production will be distinguished by low cost and profitability. What is the reason for this?

It's all about the oxidation reaction of the fuel. If in modern rockets the process of deflagration is used - slow (subsonic) burning of fuel at constant pressure, then the detonation rocket engine functions due to the explosion, detonation of the combustible mixture. It burns with supersonic speed with the release of a huge amount of thermal energy at the same time as the spread of the shock wave.

The superiority of new engines

The study and development of detonation enginesengaged in leading world scientists for 70 years. The main reason that prevents the creation of this type of engine is the uncontrolled spontaneous combustion of fuel. In addition, the agenda included the tasks of efficient mixing of fuel and oxidizer, as well as the integration of the nozzle and air intake.

- The ability to develop speeds in the subsonic and hypersonic ranges.

- The exclusion from the design of many moving parts.

- Lower mass and cost of the power plant.

- High thermodynamic efficiency.

Serially this type of engine was not produced. For the first time it was tested on low-flying aircraft in 2008. The detonation engine for carrier rockets was first tested by Russian scientists. This is why this event is so important.

Principle of operation: pulsed and continuous

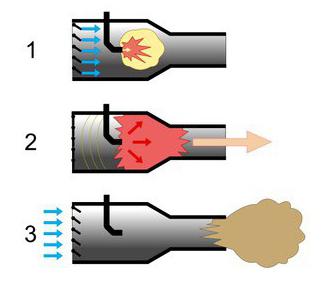

Currently, scientists are developinginstallations with pulsed and continuous working process. The principle of operation of the detonation rocket engine with a pulse scheme of operation is based on the cyclic filling of the combustion chamber with a combustible mixture, its consequent ignition and the release of combustion products into the environment.

- One time ignition of fuel.

- Relatively simple construction.

- Small size and weight of installations.

- More effective use of a combustible mixture.

- Low level of produced noise, vibration and harmful emissions.

In the future, using these advantages,the detonation liquid rocket engine of the continuous scheme of operation will replace all existing installations due to its mass-size and cost characteristics.

Tests of the detonation engine

The first tests of the domestic detonationinstallations were held in the framework of the project established by the Ministry of Education and Science. As a prototype, a small engine with a combustion chamber 100 mm in diameter and an annular channel width of 5 mm was presented. The tests were carried out on a special bench, the indicators were recorded when working on various types of a combustible mixture - hydrogen-oxygen, natural gas-oxygen, propane-butane-oxygen.

Analogs in other countries

The development of detonation engines isscientists from leading countries of the world. The greatest successes in this direction were achieved by designers from the USA. In their models they realized an uninterrupted way of working, or rotational. The US military plans to use these installations to equip surface ships. Due to their smaller mass and small size, with high power output, they will help increase the effectiveness of combat boats.

A stoichiometric mixture of hydrogen and oxygenuses for its work the American detonation rocket engine. The advantages of such a source of energy are primarily economic - oxygen burns exactly as much as is required for the oxidation of hydrogen. Now the US government spends several billion dollars to provide military ships with carbon fuel. Stoichiometric fuel will reduce costs several times.

Further directions of development and prospects

New data from the testdetonation engines, determined the use of fundamentally new methods for constructing a scheme for working on liquid fuels. But for the functioning of such engines must have a high heat resistance in view of the large amount of released thermal energy. At the moment, a special coating is being developed that will ensure the performance of the combustion chamber under high-temperature impact.