What is a split? Types and application of material

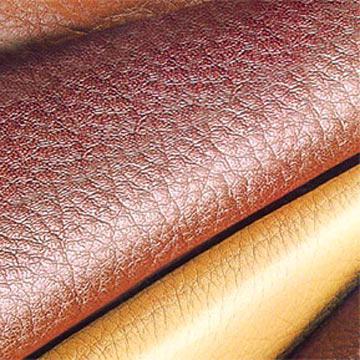

The question of the naturalness of the material excites everyonebuyer, when he buys items from the skin. Modern manufacturers own technologies, as a result of which a material is obtained that is difficult to distinguish from high-quality raw materials. Before going for a purchase, a person must master at least a minimum of knowledge in this area: how does the natural skin look like, what is the split, how to distinguish them from each other.

Grinding skins

In the leather industry, the processTreatment of the skin, which is called sherffing, or foliation. As a result, the workpiece to be processed is divided into parts, layers. They can be a different number - from 3 to 6. It all depends on the original thickness of the skin and the settings of the mechanism, which this work performs.

Now it's easy to guess what a split is. This is the part of the skin obtained as a result of the process of its foliation. Most often the term mentioned still applies to the middle layer.

Use of different layers of skin

Having dealt with the fact that such a split, you need to know how to use it. What type of production is suitable for each layer?

- The upper, facial layer is, in fact, natural high-quality leather.

- From medium and mezdrovoy - after a certain treatment - receive the same material, but has lower quality characteristics.

- From the spilk layer, skins produce split velours. It goes to the manufacture of shoes or parts, overalls, mittens, gloves.

- Mezdra (the lowest layer) and the trimmings, which remains after the production of the spilka, are used to make glue, technical gelatin and other substances.

What is a leather-split, it was known back in antiquity. For example, it was he who, as the purest material, was used by the ancient Jewish people to record the mezuzah (part of the text of the prayer).

Ways of processing split

There are several ways to treat the skin of the skin, but two of them are used most often.

The first is that the producers of raw materialsrecreate the naturalness of the skin pattern on the upper layer of the spilka. To do this, it is treated with special resins or varnishes. Outwardly, such a material is difficult to distinguish from natural leather, but it can not be ranked in this category, since chemical processing tools were used in production. Split, treated in this manner, it is customary to call semi-natural skin.

Having become acquainted with the second method of fabricating the material, it can be understood that such a split is natural.

For its preparation, the outer surface of a piece of skinprocessed for suede or velor. Chemicals in this treatment are used minimally, and the raw materials obtained can be classified as natural materials.

But the split velor or suede has onea significant drawback: the material is too "gentle", it passes water, does not have wear resistance. To extend the life of such raw materials, improve its performance, the external surface of the layers of skin still have to be treated with special chemical compounds. But the name of the natural splitsa behind this kind of material was fixed.

Reasons for the popularity of such products

Products of shoe and haberdashery factories,made of spilk material, in demand among buyers. Recently, the demand for such goods has even increased. There are several reasons for this.

- The first of these lies in the fact that the products have reasonable prices, in comparison with things made of genuine leather.

- The second reason is the accessory split to the category of natural materials.

- The third important circumstance is that raw materials have excellent external indicators. Sometimes even specialists do not distinguish it from genuine leather.

In the making of modern work clothes, a split is often used. As it turned out, it is convenient and profitable, which also contributed to an increase in demand for the material in question.

</ p>