Tying the solid fuel heating boiler: a diagram. How to make a strap yourself

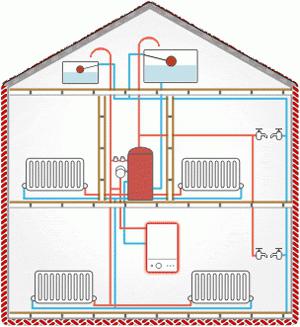

If you want the house to be warm and cozy,A competently designed strapping of a solid fuel heating boiler will be required. The scheme of this procedure will be considered in the article a little lower. By itself, the strapping is the installation of all equipment suitable for the boiler. As a result of the binding, a single heating system should be obtained. Often this procedure is done by oneself without the participation of professionals.

Some general information

Before the binding is performed, it is necessary totake into account several important details. For example, the pressure in the system and the temperature of the coolant at the outlet from the boiler should not exceed the allowable values. For this purpose, protective devices and warning systems are installed. In addition, the temperature of the liquid (coolant) at the inlet and outlet should be approximately the same. In any case, the difference should not be more than 20 degrees Celsius. This requirement is especially important for steel equipment, since the formation of condensate inside the housing undesirably affects the durability. Do not forget that the binding of a solid fuel heating boiler, the circuit of which must be selected for a reason, requires the presence of automation and sensors. In addition, it is desirable to install storage tanks for hot water and the like. Well, now let's talk about the most interesting.

Tying of systems of open type

This scheme is suitable ifnatural circulation is used. We can say that technically this is the simplest option. The reason is that we will deal with a small number of different equipment and devices. The key advantage of such a scheme is that it is completely non-volatile. The downside is that it is not possible to regulate the temperature at the outlet from the boiler. Often this leads to an accelerated corrosion process.

Tying of systems of closed type with natural circulation

The fundamental difference between this method andThe previous one is that a closed diaphragm tank is installed. In priority, its installation must be carried out on the return line of the heating system. It is important to comply with the requirement, which relates to its volume. Thus, the amount of coolant in the membrane tank should be at least 10% of the total amount of liquid in the system.

Solid fuel boiler piping schememeans the use of a relief valve to relieve pressure, as well as an air vent. Installation of equipment can be carried out separately or in one device, which will be the safety group of the boiler. By the way, it is necessary to understand that most of the modern heating equipment already has all these elements in its system, so no additional installation is needed.

Tying of a gas and solid fuel boiler with forced circulation

For the organization of forced circulationit is necessary to use the pump. In most cases, it is mounted on the return line between the nozzle and the tank. The pump is controlled by a temperature sensor that is mounted on the return line.

I would like to note that the use of a pumpmakes systems more efficient. But in this case you need to connect to the mains, which increases the electricity consumption. Also, the system requires an uninterrupted and stable electrical connection, therefore it is recommended to install protective equipment, for example, stabilizers or at least fuses. In general, this scheme of tying solid fuel boiler is extremely relevant and effective.

On the collector method of connection

This scheme is used only in systems withforced circulation. The difference from the above described method is that in this case, collectors (combs) are used. The devices of such devices are simple enough. As a matter of fact, it is a segment of a pipe of the big diameter, having one input and several outputs of smaller diameter. Accordingly, such equipment is connected to the boiler inlet and outlet.

The advantages of this scheme are thatyou will be able to turn on the heaters individually. This is achieved due to the fact that they are supplied with a coolant of the same temperature. It is also convenient to operate such heating devices. Of the disadvantages is worth noting the high metal capacity of the collector and the complexity during installation.

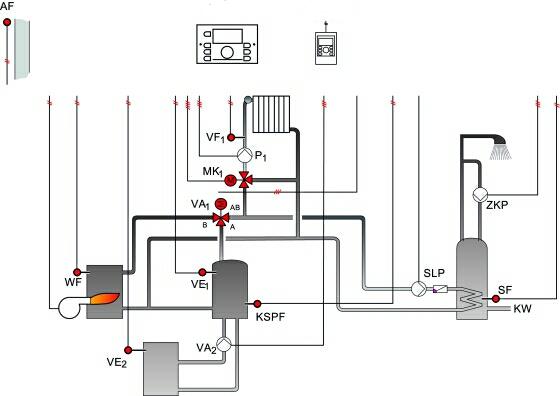

Tying of solid fuel boiler with heat accumulator

This scheme is good because it is suitable for bothnatural, and for forced circulation. During the installation work, two circulation circuits are necessary. One is placed between the boiler and the heat accumulator (TA), and the second is between the heat accumulator and the main heating system.

During operation of the equipment, the coolantenters the TA. A thermal battery is a storage tank having a thermally insulated housing. As a result, there is a gradual accumulation of heat in the TA. If necessary, it is given to the heating system. It should be noted that the strapping of a solid fuel boiler with a heat accumulator is also interesting because even after switching off the heating equipment from the TA tank, heat will be given for some time. The method is good in that it increases the efficiency somewhat and reduces fuel consumption.

Connection of emergency systems

We have already figured out a little howstrapping solid fuel heating boiler. The scheme, as you can see, can be used any, however, much depends on the circulation used. But in any case, you must take care of the presence of emergency systems. They are necessary to protect against:

- excess pressure;

- excess of coolant temperature;

- preventing the formation of condensation on the internal walls of the boiler.

The safety valve should be installed onflow line when leaving the boiler. Often, the valve is built into the boiler, but if it is not, you can install it manually. A drain hose must be connected to the valve spigot. There will go excess fluid. It can be connected to a sewer or a suitable container.

Arrangement of an additional circuit

The additional circuit is installed for protectionequipment from overheating. The circuit itself has a natural circulation and is connected to the DHW tank. If the system is operating normally, the internal pressure locks the secondary circuit with a non-return valve. As a result, the coolant does not circulate there. But when the pump is shut down for any reason, forced circulation in the system becomes impossible. The result is an additional circuit with natural circulation, and the coolant is cooled to the required temperature. If you are tying the solid fuel boiler yourself, then it is desirable to acquire such a system. It will be useful in many emergency situations.

Installing the thermostatic mixer

Here we have already figured out how the strapping is performedsolid fuel boiler and electric boiler, as well as gas. As you can see, all the circuits are very similar to each other and differ by the additional equipment used. One of these accessories is a mixer. It is necessary to maintain a certain temperature of the coolant at the boiler inlet. To install the mixer is best on the return line, and then use the jumper to connect it to the main line. This will protect the boiler from condensation on its walls. If necessary, the device will open, diluting the cold coolant hot. Here, in principle, and everything that can be told about such an event, as tying a solid fuel boiler. The scheme is selected depending on the type of circulation and heating equipment used.

</ p>