How is the sharpening of the circular saw performed?

A circular saw is a steel disc withon its edge with incisors and the intervals between them - sinuses. They may look like a solder alloy of harder than the substrate, or cut from the shape of the body itself. The whole row of saw blades is called a ring gear, and the disk is a saw blade. The frontal surface of each tooth is the front face, and the back is called the back. The distance between the neighboring vertices of the incisors is called the step. In standard saws, the entire toothed ring consists of equal pitch and height values. As a result of the work, the manual circular saw cuts the saw in the wood - a slot limited by three faces.

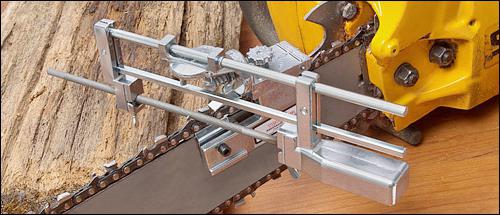

Sharpening of a circular saw, as well as finishing of its teethwith carbide tungsten carbides, is performed by means of abrasive (carborundum) wheels. The method can be combined: the first (coarse) procedure is performed with abrasives, and the finishing procedure with diamond tools. To preserve the hard alloy cutters and the properties of grinding wheels, the preliminary treatment is carried out at the expense of the length of the blade - on the back edge, and the thin - on the front.

Sharpening the saw blade on the reverse sideis the grinding of the steel part of the tool at an angle of α + 6 °. A thin procedure on a plate of a hard alloy uses an angle α + 2 °, fine-tuning of that part of the plate that is adjacent to the blade - angle α. The front face is processed by preliminary sharpening along the entire length of the lamella soldering, and the final one by the front side (under the condition of using the finishing method, which should be conducted with the participation of continuous cooling). However, for diamond grinding wheels based on a bakelite sheath, it may be possible to sharpen the circular saw in the nominal mode.

On modern machines that usetools of a combined type (two grains fractions - diamonds with abrasives), sharpening is performed with continuous cooling in one pass with removal of allowance by 0.25 mm. There are hard-alloy saws, where double-sided plates are used. Transposing, they work on both sides, then they are allowed to be processed to make new canvases. Such sharpening of the circular saw greatly simplifies the management of the tool farm due to the centralization and consolidation of the used enterprises.

If the disc has a tooth back face made flat, andSharpening is done on it by parallel layers, along the course of wear of the tool its back angle is sharpened, and with a certain number of pencils, it risks becoming unacceptably small.

To support the normal grinding conditions of thosesections along the contour of the tooth blade that are located in the plane of rotation of the web or are located close to it, arrange the angle of the lateral clearance through the oblique lateral turning of the rear wall of the tool (as in a conventional planer saw).

</ p>