Whistling of a turbine on a diesel engine during acceleration: possible causes and solutions to the problem

Modern cars are often equipped withturbocharger - so you can significantly increase the power and performance of even low-power and low-volume motors. As is known, no engine can operate normally without a certain amount of air. To burn in combustion chambers one liter of fuel, you need at least 11 thousand liters of oxygen. But in order for the air to fall into the cylinders, it must pass through the filters, the intake manifold, bypass the throttle and then get into the slot of the saddle and the valve itself. The need for a motor in the air is never completely satisfied. The turbocharger gives the air acceleration and pumps it into the combustion chambers. During operation, the turbine can produce sounds. Many car owners are worried. Let's find out how this node is arranged, whether the whistling of a turbine on a diesel engine during overclocking is dangerous, and what it says.

About creating a turbine

Most car owners are seriously sure thatturbomotors are a relatively recent invention. It is believed that they appeared in the second half of the 20th century, when almost all models of the German car industry were equipped with turbochargers. But it is not so.

But with all the efficiency of these first turbines, theyhad bulky dimensions and many times increased the weight of the engine. The development of turbocharging for passenger cars stopped, but on a truck transport turbines were used very actively. In the US, automakers were slow to industrialize the supercharging system. Then (however, as now), the rate on the volumetric atmospheric power units was made. There is even a saying "nothing will replace the volume."

In Europe, fuel was treated more sparingly,than in the USA. In addition, in the 20th century, Europe experienced a fuel crisis. Automakers began to reduce the volume of motors, while increasing power. This was helped by the boost system. The technology was improved, the elements of the structure became lighter. However, among the shortcomings was still a high fuel consumption - turbo-supercharging among ordinary car owners did not find popularity.

Element in a diesel engine

As is known, the diesel engine was developedin 1893. Over time, its design has been refined, many details have undergone repeated changes and modifications. Engineers worked on ways to feed the fuel mixture, as well as on the balance itself. Then the engineers developed a turbine designed to increase the productivity and performance of the unit due to more complete combustion of fuel in the cylinders. This process is based on the compression of air in the internal system - this made it possible to increase the density of the supplied air. So the mixture burned completely, and the atmosphere emitted less harmful emissions.

There are turbines of low pressure and high. The devices of high pressurization are more effective, and also a complex structure.

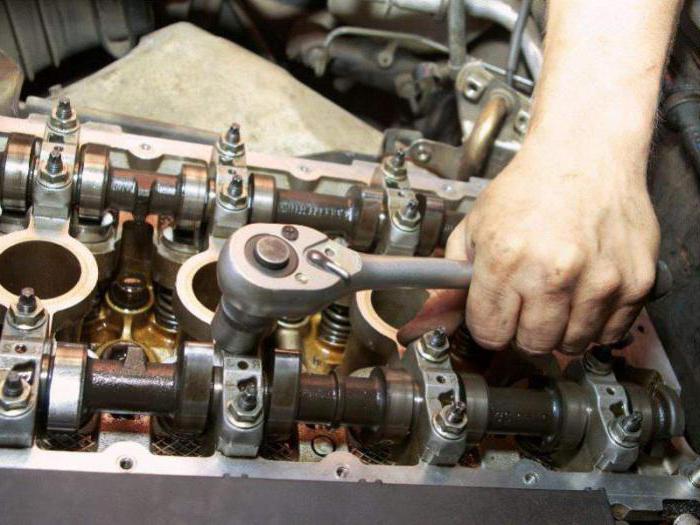

Design

The modern turbocharger is aA device consisting of the following components. These are two casing, each of which is equipped with a compressor and a turbine. These casings are made of heat-resistant cast-iron alloys. The turbine is equipped with a special wheel - it also has resistance to high temperatures.

Also in the design there are specialbearings. Their bodies are made by casting from special bronze alloys. A shaft passes through them, which connects the compressor wheel to the turbine rotor. Support and thrust bearings are also available.

Principle of operation of the turbocharger

The algorithm of work is as follows. Combustion products that are discharged from the exhaust manifold go to the turbocharger inlet. Then they pass through the turbine housing - the channel in the body has a variable cross section. Exhaust gases as they move along the channel increase their speed and act on the wheel of the turbine - under this influence it rotates. The number of revolutions of the turbine rotor depends on many factors. The average rotation speed is 1500 r / s.

Air from outside, passing through air filters,thoroughly cleaned of impurities and compressed into the intake manifold. Then the channel closes. The mixture is further compressed and ignited. Then the exhaust manifold opens. At the entrance to the combustion chambers an intercooler is installed.

It is necessary for cooling hot air,coming from the turbocharger. This increases density and decreases the amount of oxygen. The cylinder gets more air, which after mixing with the fuel will burn more efficiently. Due to this, power is significantly increased and fuel consumption is reduced.

If the turbine whistles

In the process of working through it is a hugethe amount of air that will then mix with the fuel, increasing the weight of the mixture. Oxygen is pumped under high pressure - under the hood can be present whistle both on idle and when driving. One of the reasons is a violation of the integrity of the system.

These sounds can alert. But do not immediately go to the diagnosis in the SRT. You can try to fix the problem yourself. The first thing experts recommend is to check each air tube in the engine for leaks. Often, when there is a whistle of the turbine on the diesel engine during acceleration, there is an excess air suction. To eliminate the problem, replace the gaskets, tighten the clamps and fasteners.

In case of wear of the nozzles, they are changed to new ones. Repair they are not subject to, and put the former in use is not recommended.

If the system is sealed, and whistling is still audible,then it is necessary to conduct a deeper diagnosis, because the turbine is a very important technical element that should work stably. Many do not know, but a small whistle of a turbine on a diesel engine during acceleration is a common thing. But if the device roars, then it is already connected with problems.

How does the turbine whistle?

Often, compressors issue these sounds when typingrevolutions in a range from 1,5 up to 2,5 thousand turns. At the same time, it does not matter how quickly to accelerate. Whistling will still occur. Sounds do not stop, even if the speed drops. At the same time, the characteristics of the engine do not change in any way. Just the amount of air passing through the turbocharger passes through special holes that eventually lost shape. As a result, the driver hears from the engine compartment a nasty whistle of air during acceleration.

Light whistling sounds can be observed even onnew turbines. But it quickly passes. And after a while, if the device is working properly, only the sounds of the motor are heard. If the turbine whistles and the speed falls, replace the hose, which connects it to the intercooler. Sometimes the air heat exchanger itself can be to blame. If there was a whistle during the acceleration, similar to a broken intercooler, you need to make an audit - repair it easier than a turbine. The part can be sealed or replaced with a new one in case of serious malfunctions.

Why does the intercooler break through? The fact is that the element is installed in the front of the car. Not only is it located in front of the radiator, it is also fixed almost at the bottom of the bumper. Therefore, various stones can enter here.

This is one of the main reasons whythere is a whistle of a turbine on a diesel engine during acceleration. By the way, the intercooler is not installed on all turbocharged engines. This should be taken into account in the diagnosis. In some cases, the compressor has oil cooling (for example, on the diesel engine "Kammniz" from "GAZel-Business").

Causes of whistling

The number of revolutions with which it rotates completelyservice turbine impeller, is more than ten thousand per minute. Definitely, the whistle of a turbine on a diesel engine during acceleration is a sign of depressurization in the connections of the system. The turbine whistles due to the passage of compressed air through the slots. You can solve these problems yourself. To do this, you need to find the place that is the cause of these sounds.

Also, the whistle of the turbine when dialing speed canarise due to the passage of air anywhere from the intake manifold to the intercooler. Also, the sound will occur if there are gaps between the cylinder head and the intake manifold (loose fitting of the block surfaces). If the gasket is broken, then this is also one of the reasons for the whistle. Sound can also occur if outside objects get into the mechanism.

Other symptoms of malfunctions

Not only whistling during acceleration canindicate a malfunction of the unit. There are other signs. On them you can determine that the turbine needs repairs. We will look at the typical malfunctions of the unit by the color of the exhaust.

Blue Smoke

This is the first and most characteristic sign of a breakdown. When dialing the speed, blue smoke will be emitted from the exhaust pipe. At the same time, if the motor runs at lower revs, it will not. The reason is in the burning oil that will get into the cylinders of the engine due to leakages from the turbocharger. Also, you can hear a characteristic whistle when dialing speed.

Black smoke

Smoke of this color indicates that incylinders burns a rich mixture due to air leakage in the pumping lines or in the intercooler. Another reason is the electronic control system. It can fail. Additionally, inspect the condition of the injectors.

White smoke

The reason for the formation of this smoke should be sought inblockages of the turbine oil drain. If there are oil leaks on the body of the unit or it is present on the air pipe nozzles, this is caused by a clogged system in the air supply duct. The axis of the turbine could also become coked. As a result, exhaust gases are of unnatural color.

Conclusion

We examined why the turbine whistles ondiesel engine during overclocking, the reasons for the appearance of these sounds. In most cases, they are associated with air leaks. You can remove depressurization with your own hands. But if the breakdown is more serious, then we can not cope on our own. Modern turbines have a complex design, and repair is best entrusted to professionals. They are able to determine by the sound of which the turbine whistles.

</ p>