Pneumosuspension: the principle of operation, device, pros and cons, owner feedback. Air suspension kit for car

The latest models of mid-range carsalmost all without exception are equipped with a pneumatic suspension. In any case, this option is offered optional from large manufacturers. Also, the machines, whose design was not initially oriented towards the integration of such systems, are often provided with pneumatics. It has many advantages, so experienced motorists, given the possibility of such restyling, are advised not to give it up. Most likely, in the coming years the dominant mechanism of the running bearing part will be the air suspension. The principle of operation of this mechanism is rather complicated, which is due to the conjugation of diverse systems. Suffice it to say that it is necessary to interact with traditional compressor units with standard automotive mechanics. This partly explains the drawbacks of such mechanisms. However, it should be considered in more detail.

Suspension device

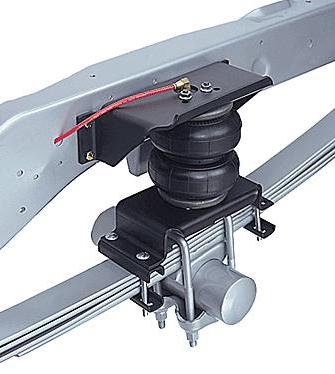

The system is formed by a whole group of components,which in the end provide suspension functionality. The mechanical basis is the actuating mechanisms of the suspension, due to which adjustment and support of clearance is possible. One of the key elements is the compressor, which supplies the air mixture to the receiver - the so-called pneumatic cylinder. By the way, the most modern bag-type receivers are equipped with a Mercedes suspension, which, however, has a significant drawback. The surface of the cylinder, despite the presence of protective shells, can accumulate sand, the friction of which in the long run wears out the metal walls, leading to the need for replacement. On the other hand, this moment comes only after a few years, so the update can be performed in complex with other obsolete mechanisms. From the receiver, the air environment is sent to the executive group of mechanisms, which also have the necessary physical effect on the construction of the undercarriage.

Air Suspension Kit

Full range of air suspensionincludes even more components than the basic design. All additional components can be divided into two parts - functional fittings and measuring instruments. As for the first category, it is represented by mechanical valves with fittings, tubes, protective equipment for the compressor itself and a moisture trap. It is necessary to understand that moisture for such suspensions is the most dangerous environment of exposure. Measuring instruments are manometers. This device is necessary for adjusting the pressure indicators - it can be mechanical or electronic. A modern air suspension kit often includes digital manometers, whose work is closely related to pressure sensors. The presence of the detector indicates the possibility of automatic adjustment of the compressor parameters for certain operating conditions.

Principle of operation

Like most pneumatic systems,A car suspension of this type works by supplying an air mass, i.e., compressed air. The source of the working environment is the compressor unit - it integrates into the suspension system. And the receiver and the direct mechanical clearance controller is the so-called spring cushion. Each wheel has its own part of the general infrastructure of the springs, which is serviced by an air suspension. The principle of operation is as follows: the compressor supplies air to the receiver, then to the distribution system, and it, in turn, fills or releases the spring cushions. As for the distribution system, it is formed by air supply channels, as well as a system of sensors and monitoring nodes that are physically responsible for manipulating the suspension.

Types of air suspension

Classification of air suspension is determinedthe possibility of equipping the wheels with spring cushions. So, the simplest single-circuit system can be integrated only into one axis of the machine. The user can set it to the rear or front axle to choose from. Classic air suspension was installed on the rear axle of trucks, which allowed to regulate its rigidity with an adjustment to the workload of the body. Somewhat differently, a dual-circuit air suspension can function. The principle of operation of this mechanism makes it possible to integrate the spring nodes into one or two axes. If the mechanism is installed on one axis, the driver is able to independently adjust the wheels, but only on the selected axis. Accordingly, the two-loop system allows for independent adjustment at the same time for two axes. The four-loop system gives the most control. Therefore, for its control, automation is used, with the help of sensors tracking positions and operating parameters at each spring point.

Air Suspension System Installation

The installation process consists of the following steps:

- A spar of a suitable size is cut in, after which a pipe is welded into it. Do not forget at this stage about smearing and cleaning of metal surfaces.

- Racks are installed. You can perform this operation in the service, but you can do it yourself - but in any case the procedure will be long and very tedious.

- Direct installationair suspension with all the main components - receiver, water trap, compressor and a set of valves. Fixing of elements is made mechanically by twisting or welding - depending on what possibilities for this provide a specific design.

- The infrastructure is installed in the form of electrical wiring (connected to the battery), circulating units, control unit, etc.

- All installed components are interconnected with the complete hardware. If necessary, use adapters and fittings.

Suspension Control

Adjustment can be made as inautomatic, and in manual mode. The block with automatic control is most often provided. It is located near the compressor itself and serves to command valves through the wiring. Output control panel is also in the cabin - through it the user himself can give commands. As a minimum, the operator should be able to adjust the clearance for specific altitudes. The value of 1 mm is the base value, which by default has almost any air suspension. The principle of operation, which is interrelated with the function of the compressor and the transmission of compressed air through several channels, of course, does not allow the level of the body position to be set with a high degree of accuracy. However, thanks to high-precision indicators, drivers of modern systems, nevertheless, can rely on obtaining more or less reliable clearance data, as well as on its automatic correction.

Benefits of the

Basically the advantages of air suspensionare reduced to comfort when driving. Neither the driver nor the passengers feel sharp jerks when driving on uneven surfaces, for example, when compared with traditional types of springs. Also noted the flexibility in installation, management and operation in general. Spot adjustment of the mechanisms makes it possible to rationally use the resource of the elements and assemblies on which the air suspension is based. Pros and cons in this respect can converge and diverge, since the separate management of components also causes the complexity of the system setup. And one more important plus is directly in the possibility of lifting the clearance, which is not available for alternative versions of the suspension.

Disadvantages of air suspension

Again, the complexity of the suspension mechanisms goes outto the fore. It's not just the problematic installation of such systems, but also the further complexity of repair. Even if you can find a good specialist, individual components can fail so that a review of the entire infrastructure will be required. However, if a single-loop rear air suspension is used, serious problems in this respect can be avoided. Such sets are distinguished by simplicity, minimal amount of accessories and auxiliary components.

There is also a whole group of shortcomings associated withsensitivity of the compressor. It has already been said that the system does not tolerate a flood of liquid, but it is also afraid of frosts. To the same it is necessary to add and requirements to a road covering which is shown by a pneumosuspension. Pros and cons in this part are also intertwined, if you compare with other mechanical types of pendants. Pneumatics is good in that its execution units are characterized by strength and durability. However, the functional working part with the compressor and electrical components without proper protection can be damaged.

Reviews about air suspension

In operation, usersair suspension notes stability of movement, smoothness and convenience at management of mechanisms. Especially it concerns automatic systems. On the other hand, all the listed properties are relevant only in cases when a standard factory air suspension is used. The owners' feedback on the packages that were introduced by handicrafts contain a lot of criticism. It is expressed in the need for constant replacement of individual parts, and in violations in the on-board electrical circuit, as well as in the mechanical weakness of the structure as such.

Conclusion

Do not always justify yourself and the choice of factorypneumatic package as an option. It should be borne in mind that initially such systems were developed for trucks in which they show their best qualities. Thanks to a qualitatively installed air suspension, the minivan can provide a high body lift, its automatic alignment under uneven load conditions, etc. These and other advantages can be useful to the driver of a car, but we must not forget about the high financial costs. In addition to a considerable price tag of pneumatics as an option, the driver will also need regular investments in the maintenance of the mechanism.

</ p>