How to choose a device for welding plastic pipes? Welding equipment for plastic pipes

Today, more and more often for the installation of water pipesuse plastic pipes. This is due not only to their longevity, but also to good performance properties. Due to the high thermophysical parameters, polypropylene pipes are excellent for supplying hot water. To connect them together, gluing, crimping and welding are used. The last species is considered the most preferable. But in this case you need a device for welding plastic pipes. About how to choose it, we'll talk in this article.

A little about the features of welding

Polypropylene pipe can be mounted insystem with the help of several types of welding: butt, coupling and socket. If you do not want to purchase couplings and fittings, then you need to choose a butt joint method, since it is considered the most economical. Of course, you will need a device for welding plastic pipes. The principle of operation of the unit is similar to a soldering iron, that's why it is sometimes called that way. The device is necessary for heating the connected ends of the pipes. Docking is realized in several ways. The most popular is the contact-butt joint. Its essence consists in joining the molten ends under pressure. The strength of the seam in most cases is not inferior to the strength of the pipe. The main condition is to ensure a high temperature, so the selected soldering iron should be heated to 250-260 degrees Celsius.

Apparatus for welding plastic pipes: manual or mechanical?

We all know that welding equipmentprovides an all-in-one connection due to heating of the treated surfaces and their further connection. It is worthwhile to draw your attention to the fact that welding equipment for metal products and plastic have a number of features and design differences. Units for working with polypropylene can be divided into two large groups:

- mechanical equipment - used to create permanent joints of large diameter pipes, as well as where it is necessary to exert great effort;

- manual welding machine - the ideal solution for use in domestic conditions (with the help of such an aggregate it is possible to connect pipes with a diameter not exceeding 12.5 cm).

Details of mechanical equipment

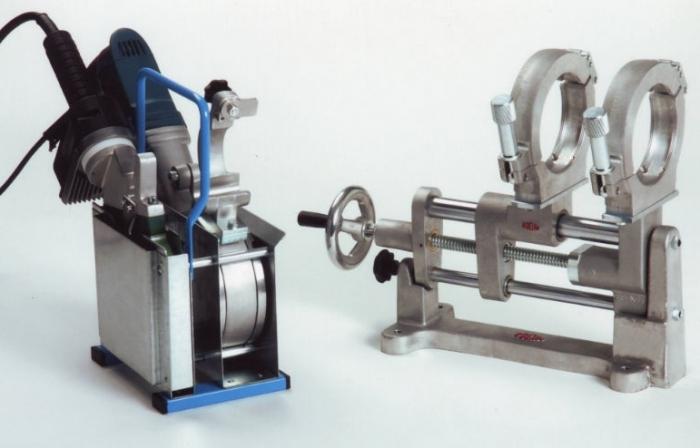

If you are going to make money onwelding, then you definitely need to give preference to a professional model. Most of the mechanical equipment for connecting polypropylene pipes is designed for intensive use, in contrast to manual assemblies. The device is a support frame on which is placed the instrument cluster and hydraulic unit. On both sides of the device there are half-rings with grips. Between the grips, inserts are installed, which are necessary for even pressure distribution during connection and alignment. The inside diameter of each liner corresponds to the diameter of the pipe being treated. The operating element (heating element) is a cast disc with a special coating. Inside it there are heating elements. It is worth noting that the welding of plastic pipes is carried out with the adjustment of the temperature regime. Any professional welder has such an assembly, but this does not mean that he does not have a hand-held device. The reason is that this device is better suited for large diameter pipes.

Iron, or a hand-held machine for welding plastic pipes

Most of us choose a welding machine forperformance of one-time works. Of course, in the future this tool is useful, but it is unlikely to be used intensively. The device is called an iron for a reason, because it is similar to this household appliance by the principle of action. The main differences are only in the design. The design implies the presence of a heating plate and a thermostat. For the comfort of work, there is a special handle. At the end of the heating plate there are two openings into which the two ends of the pipes are inserted. Teflon coating does not allow the molten pipe to adhere to the plate.

Pay attention to the complete set of the product

When buying a product it is extremely important to drawattention to the fact in which it is provided. Everything depends on the manufacturer's company, nevertheless, it is possible to identify the main elements that must necessarily be present.

If you are going to work with the pipes of one,maximum of two diameters, then, in addition to the unit, only the key for the attachments can be included. Again, this is a very modest bundle, which is not always suitable. If you are an amateur, you better prefer the kit, where there will be nozzles for working with polypropylene pipes of the following dimeters: 20, 25, 32 and 40 mm, which are the most common.

Equipment Capacity

Undoubtedly, the apparatus for welding plastic pipesshould be powerful enough. This parameter determines not only the maximum possible processing diameter, but also the speed of work. Proceeding from this, it can be concluded that the larger the anticipated volume of work, the higher the power will be required.

In many cases it will be enoughtool average power of 1.5-2.0 kW. But in most cases it is advisable to use a slightly different approach. It consists in the fact that the diameter of the processed pipe is multiplied by 10. As a result, it is possible to obtain the minimum required capacity of the equipment. In this case, the welding of the plastic pipes will take place, without any problems. It turns out that if you want to solder tubes with a diameter of 50 mm, then 50 x 10 = 500 watts. But it is strongly recommended not to buy a low-power tool, it is better to take a margin of 20-40%.

Manufacturer selection

When choosing it makes sense to pay attention toa company that produces welding equipment. It is worth noting that welding plastic is a very important task, and the quality of the tool will depend on the state of the connection and its durability.

To date, the best soldering iron makes inThe company "Daytron." Equipment from this manufacturer has earned worldwide recognition. Distinctive features: high quality and wide functionality. It should be noted that a soldering iron for welding plastic pipes from the Czech Republic is worth a lot, so a good alternative will be Turkish products. For example, the Kandan welder is designed to work with pipes 16-160mm in diameter. The quality is very good, but the price is acceptable.

Conclusion

Here, in principle, and everything that can be told aboutselection of equipment. Remember that welding plastic can cause a burn. For this simple reason, when purchasing equipment, an instruction is attached to it. If there is no one in the kit, then consult with professionals or seasoned welders. They will tell you how to weld plastic pipes. The instruction, nevertheless, is nevertheless desirable and in any case should be read, and all the requirements listed there must be fulfilled. Do not forget about it. And all will be well.

</ p>