Weights for calibration: description, features, types

Laboratory scales - equipment designed to measure the mass of various objects and substances. Work such devices can, for example, from the network or from the battery. At the same time, modern equipment of this type differs accuracy. But to use similar scales, unlike usual mechanical, nevertheless it is necessary exclusively in the complete set with special calibration weights.

From what accuracy of indications can depend

Scales of any kind are necessarily calibrated yet at the production - at the last stage of manufacturing. However, actually already in laboratories or, for example, at home, similar equipment can still be inaccurate. And this is often due not to the fact that the consumer was sold defective goods. The thing is this The case lies primarily in the fact that the accuracy of the scales can vary considerably depending on the locality where they are used. TO factors, which affects this characteristic of devices, it is possible to relate the following:

geographical latitude of the area;

altitude above the sea level;

power surges in the electrical network;

changes in air temperature.

In order for the scale to give the most accuratereadings, they must be calibrated separately. Most often, this procedure is necessary when buying a new device. The laboratory scales are also often needed when setting up a workplace. In some cases, this procedure is required even with each switch-on. After all, laboratory measurements, of course, should be as accurate as possible.

Actually for the adjustment of weights and special elements are used - calibration weights. As already mentioned, they usually come complete with the measuring device itself. However, in some cases, similar elements have to be purchased separately.

What are they

Calibration weights are produced in exact accordance with the requirements of GOST 7328-2001. Standards for their production must be complied with necessarily. Externally, the calibration weights are no different from the usual ones.

According to the requirements of GOST, weights of this type are necessarily packed in individual cases. Call them either proper calibration, or alignment.

With which weights are used

Usually such weights are used with instruments, devoid of special internal calibration devices. This is the widest sphere of their use. However, internal calibration to ensure the maximum accuracy of the adjustment of the scale allows, unfortunately, not always. therefore in the presence of in the laboratory, even such modern functional instruments, the calibration weights in combination with them are still recommended.

Basic Types

Distinguish calibration weights can:

in form;

material used for manufacturing;

nominal;

method of use;

class accuracy.

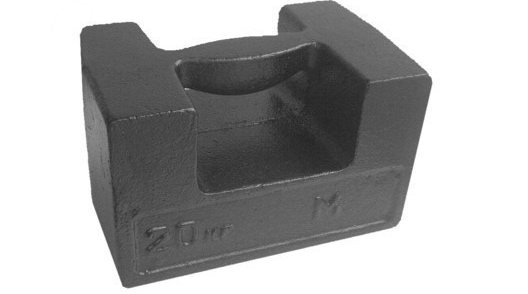

If we talk about form, then to the modern market, as already mentioned, we can supply dumbbells with or without a head her. Heavy In some cases, the calibration elements of the first type have a duct in the upper part. Exactly in this way weights are manufactured weighing 5-10 kg.

Nominal values

According to clause 4.1 of GOST 7328-2001, the exact weight of the calibration elements should be 1x10n, 2x10n or 5x10n. The value of n in these formulas must be an integer from -6 to +3 inclusive. Thus, the values of the calibration weights can be as follows: 1, 2 , 5, 10, 20, 50, 100, 500, 1000, 2000, 5000 etc., milligram, gram or kilogram.

GOST requirements for nominal weightsimilar elements, however, when they are produced, they are not always observed. Some enterprises produce calibration weights for scales, guided by the recommendations of TU. Such elements can have any denomination.

In any case, with each weight packaged in a case, a certificate confirming her compliance with the requirements of GOST or TU. In this document, among other things, the exact weight of the element is also indicated.

Actually, the requirements for the necessary weight of the calibration weights are indicated in the passport of the laboratory scales.

Material of manufacture

Do the weights of this variety, of course,exclusively of metal. This material is durable and simple, including in care. After all, no dirt or dust on such elements, by definition, should not in any case. The following types of metals can be used for manufacturing weights:

aluminum;

stainless steel;

nickel silver;

non-magnetic steel.

Stainless steel is usually used formanufacturing weights without heads, non-magnetic - with heads. Aluminum is used most often in the production of very small calibration elements, the mass of which ranges from 1 to 5 mg. Neusilber is used for making weights 10-500 mg. If the weight of the calibration weight is 1 kg, 5, 10 kg, etc., e., most likely, it will be made of steel. It is this material in this the case prescribes the use of GOST.

Accuracy classes

According to this feature, the calibration weights are subdivided depending on the values of the metrological characteristics. There are only seven classes of accuracy of such elements:

E1. Weights of this class are used to check the laboratory weights of the first class.

E2. Calibration weights e2 are used in combination with weights of accuracy classes F1, first and the second special.

F1. Weights of this type are usually used to check the weight of other weights - F2, as well as laboratory weights of the second class of accuracy.

F2. Such weights are used to check weights the second high and the third middle-class accuracy.

M1. These elements are used in conjunction with weights of technical accuracy class or when weighing medicines.

M2 and M3 - Weights used in the trade balance when balancing the weight of the load.

Weighing gauges 200 g, 1 kg, 5 mg and other nominal weights, related to classes E and F, in our country today are produced mainly on German technology and with the observance of the requirements not only of GOST, but also of international standards R111 OIML.

Ways to use

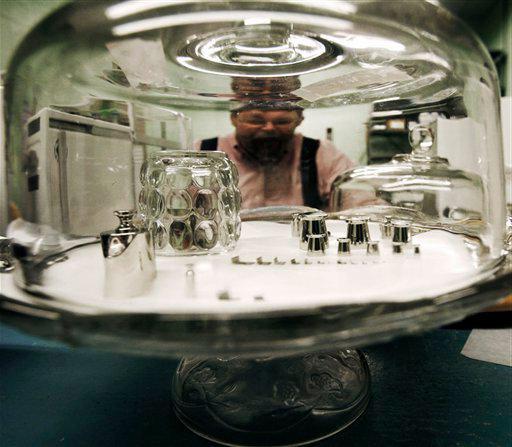

By this feature, conventional calibrationWeights and standard. The latest version of the elements is used to check the model electronic or mechanical balance. The standard weights, unlike conventional calibration weights, are supplied to the market not with certificates, but with a special certificate of verification.

Sets of calibration weights

Delivered to the market, such items can also be included in kits. Such products in the modern market are also quite in demand. The sets differ primarily in accuracy class. Also in the kit can include weights of different nominal weights. That's why using them is usually very convenient.

The kit can include calibration weights of 20 kg, 200 g, 1 mg, etc. But in any case they fit, as well as individual elements, into special cases. This allows you to prevent damage to the dumbbells, and therefore, the total loss of their operational properties.

Customer Reviews

According to most specialists using high-precision scales in their work, weights manufactured using modern technologies, practically always have excellent quality. It's not for nothing that such items are delivered to the market already with certificates.

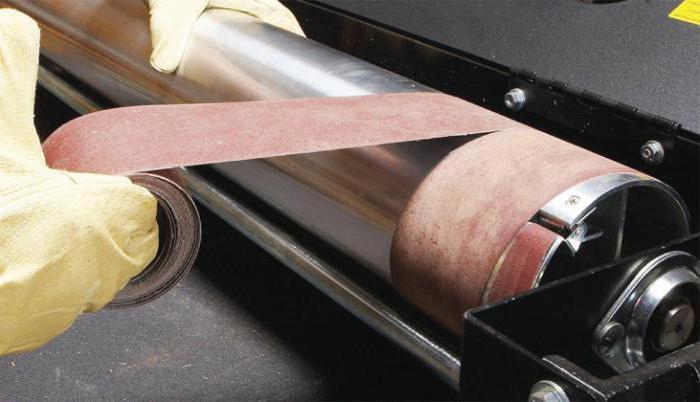

About sets of kettlebells from specialists also there are basically only good reviews. To use such kits, as already mentioned, practically always it is very convenient. Especially since In sets of calibration weights can be included, including tools designed to work with them. This can be, for example, tweezers, cotton gloves, brushes, etc.

How the balance is calibrated

Actually, the procedure for setting up a laboratory measuring instrument with the help of weights is called external. There is also yet and internal calibration. However, this operation is performed using non-weights, but special internal reference cargoes.

The calibration technology is selected primarily with account for The design of the scales and the instructions for use attached to them. But in any case, most often this procedure looks like this:

scales are included in the network;

the display is reset;

by pressing a special key, the balance is put into calibration mode;

after the zero point is displayed, the her confirmation by pressing a key;

After the display of the limit load on the weighing plate is placed calibration weight;

the zero point is confirmed.

Once on the screen will be displayed an inscription confirming the accuracy of the calibration, the weight is removed from the platform. Immediately after this, the laboratory balance automatically switches to the standard operating mode.

If necessary, after the calibration, the balance can also be checked for accuracy. For this, you need to put the adjustment weight on the platform again. If the balance shows her The nominal weight marked in the certificate means everything is in order. The balance can be used in the work.

</ p>