Honing machine: design, types and technical characteristics

Honing is the final processprocessing of parts with holes, and is performed exclusively on honing machines. In some cases, this process can be equated to grinding. The difference between the procedures is only that in honing, only holes with final removal of the allowance balls can be processed.

Machine construction

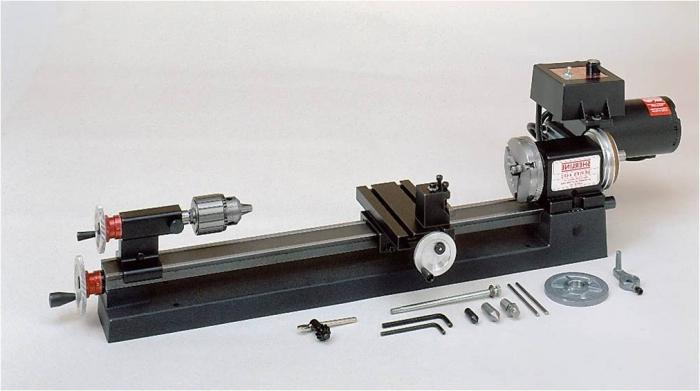

As was said earlier, for a given speciesprocessing used honing machine, which in its design is very similar to metal cutting machines of the second group (drilling). The machine consists of a bed (base), a spindle rotation drive, a device for controlling the machine and installing the part.

During the process, the workpiece remains stationary,and only the spindle rotates, in which the honing head is fixed - a tool for processing holes. The spindle is made in such a way as to allow the tool to perform both forward (up and down) and rotational motion (around its axis). This design feature allows the surface to be treated evenly to achieve the required roughness and accuracy of the hole being made.

Machine Types

Depending on the design and other technical characteristics, the honing machine can be:

- with horizontal and vertical spindle placement;

- one or two-spindle, as well as with several spindles;

- for external and internal processing, as well as complex (for external and internal processing simultaneously);

- with mechanical (manual), semi-automatic and automatic control (CNC machines).

The most common models are: 3Г833, 3А833 (vertical honing machines), СС 740В, СС 743 (хонинговальные machine tools with ЧПУ), 3К833 (semiautomatic device).

Specifications

In order to choose a honing machine for this or that processing, it is necessary to take into account the main characteristics of each of them. These include:

- Accuracy classes. There are five in total - from H (normal accuracy) to C (ultra-high accuracy). Many models of honing machines produce H and B (normal and high) precision.

- Processing dimensions. In this case, this is the maximum and minimum diameter of the hole being machined.

- Processing length. This characteristic is taken into account only if the intended machining holes are too long.

- Maximum spindle travel. As in the previous case, it is taken into account only when the length of the machined hole is too large.

- Dimensions of the working surface of the table. This characteristic is taken into account only if the workpiece is of a large size.

- Speed of rotation of the spindle. This characteristic should be taken into account when it is necessary to process a hole with high technological requirements. After all, the final accuracy of the surface will depend on the speed of rotation of the spindle.

- Engine power. For stronger materials, the workpiece requires a honing machine with a large engine power.

- Other technical characteristics. For example, the distance from the tool (khona) to the surface of the table and workpiece, the power of the cooling system, the presence of numerical program control.