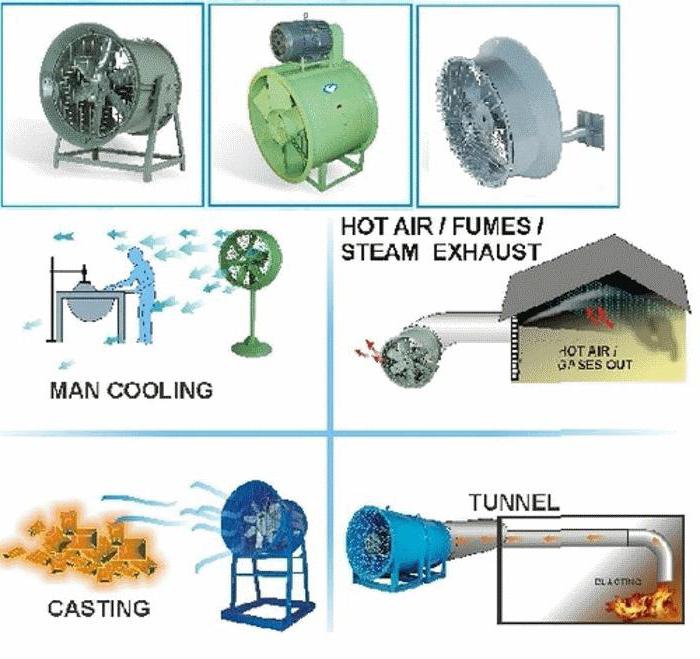

Axial exhaust fan, used in industry

For the purpose of qualitative purification of air masses inrooms, as well as maintaining the microclimate by heating or cooling, mechanical ventilation is used. Industrial premises use industrial fans.

The movement of air currents canby pulling or pumping. The axial exhaust industrial fan can also be installed in cafes, offices, warehouses and other large rooms.

Device

The device includes elements:

- screw and blades (impeller);

- axis;

- the body;

- electric motor for rotation of the impeller.

How does the fan work?

The engine is selected for the required amountfan speed. It transfers the energy of rotation of the axis with the impeller installed on it, which moves the air mass in the axial direction with the blades. The minimum dimensions of the blades are several dozen centimeters for household models, and the maximum ones are several meters for industrial ones. Axial fans create low air pressure.

The impeller is made of plastic, alloysaluminum or stainless steel. Due to the small weight of the blades, no large engine power is required. Even for industrial fans, it usually does not exceed 800 watts.

Types of axial fans

Axial fans for exhaust ventilation are primarily classified according to their intended use.

- Wall Mounted. Are located inside or at the outlet of the ventilation shafts. Improved aerodynamic properties of devices are achieved if a diffuser is installed at the output.

- Ceiling. The impeller is mounted on a long axis and produces air circulation in the room.

- Roofs. The instruments are mounted on the roof. They also include smoke exhaust fans.

- Panel or with a lattice. Mounted on the window leaf or wall with a vent. Provide for quick extraction or filling of rooms with fresh air at low energy costs.

- Outdoor. Devices are household appliances for heating or cooling air.

- Household. Fans are built into household appliances (cooling of computer parts, cooling of the car engine, hot air flow from the dryer, etc.).

- Case. Low-noise low-power models serve to circulate air in rooms or to cool electrical appliances.

- Extraction. The devices intensively suck in air, but they are blown out poorly.

- Injection. Blow the air intensively, and suck slightly.

According to the methods of operation and the composition of the transported media, the fans are as follows: general purpose, smoke removal, resistant to corrosion or elevated temperature, explosion-proof design.

Advantages

Axial fans are widely used due to the following advantages:

- Low noise level, which ensures the construction of blades;

- compactness;

- reliability and low price;

- economy;

- simplicity of design and repair.

The axial exhaust fan is high-speed and pumped air more centrifugal, but the pressure drop is lower.

disadvantages

The disadvantage is a small air pressure,created by the fan. The design is also sensitive to shock axial loads. For high loads, the blades are made of metal or reinforced plastic.

Duct fans for extraction

Axial duct exhaust fan is selectedon several parameters. First of all, it depends on the purpose for which it should be applied. The shape of the hull and the ventilation duct in which it is placed must be the same.

They are round, square and rectangular. The first ones are suitable for household models, the rest are suitable for industrial applications. For a square cross-section of the channel, a round case will fit perfectly if it is fastened to a suitable grid.

Fan cases are made of plastic(household models) and metal (industrial). Preference is given to materials that have reliable protection against corrosion, since moisture is permanently contained in the air and condensation is always present in the ventilation systems.

The main indicator is the performance - how much air can pull the device per unit of time. The household model is designed for performance up to 350 m3/ h, and industrial - up to 17 thousand cubes.

The flow rate of the medium to be transported depends on the diameter andshape of the blades. The more their front bend, the more air is able to pass the fan, but at the same time increases the noise level. Blades with a rear bend work almost silently and economically. The noise level of the channel fans is not higher than 40 dB.

The capacity of the fan depends on the volume of the room and the required multiplicity of the air in it.

The duct fan can be installed in anyplace. There are no need for connecting flanges and adapter couplings. The connection to the box is made with the help of worm clamps. Usually a fan is attached to the inlet of the duct. So it's easier to maintain. The body is fixed to the ventilation duct with a tight fit, which reduces the loss in the operation of the device. Fans are designed to take air in certain areas, after which the airflow is collected in a single air duct. This is important for removing contaminated air from the workplace.

Axial exhaust industrial fan hasprotection of the working area by means of blinds provided with manual or automatic drive. When working, they open, and after the engine is turned off, they close.

Check valves for ventilation

To ensure that in the case of a return draft,foreign smells from the outside through the ventilation duct, it installs a non-return valve. This blocks the flow of air in the opposite direction.

Axial exhaust fan with check valveIt works in such a way that air flows in only one direction. As soon as it changes to the opposite, the channel overlaps. The locking device may be a grill (blind), a butterfly, a petal or a membrane.

Lattices are installed at the inlet or outletchannel and have a different shape. The butterfly valve consists of two plates fastened by a spring. The petal, or membrane, is a flap that rotates on an axis that overlaps or opens the channel, depending on which direction the air stream is moving.

Window axial fans

Extracted window axial fans installdirectly into the window or window opening, due to small dimensions and low weight. Devices are used in production and household premises, offices, canteens, etc.

To prevent cold air from entering the room, the exhaust fan is provided with a check valve in the form of a blind, which closes when the draft in the ventilation duct changes to reverse.

For a home kitchen, a 220 V fan is suitable. In industrial systems, three-phase 380 V supply is used.

Supply and exhaust fans

Beneficial use of axial intake and exhaust fans of the reversible type. Depending on the direction of rotation of the blades, dirty air is removed from the room or fresh air is pumped.

The check valve is not suitable here, but you can install blinds that will close when the fan is not working.

For air-supply devices, provision should be made forelectrically heated charge air. Supply fans in the rooms should provide 1-1.5-fold air exchange per hour. For the kitchen, the performance of the equipment must provide 6-12-fold air exchange, when cooking is done. If the intake of fresh air in it will not, the exhaust fan will rotate, not distilling the air masses. Therefore, airing the room is provided by opening the window or door to the rooms. When plastic windows are installed, microvillage devices should be provided in them.

Conclusion

Axial fans are widely distributed,Due to low noise and high performance. For household premises it is advisable to install an axial exhaust fan in the ventilation duct or in the window opening. For the window, a reversible-type intake and exhaust device is well suited.

</ p>