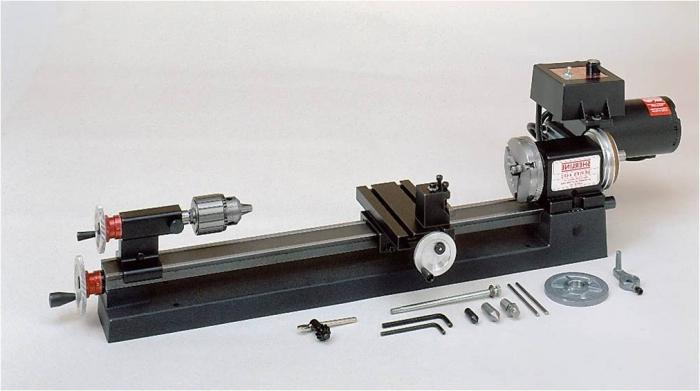

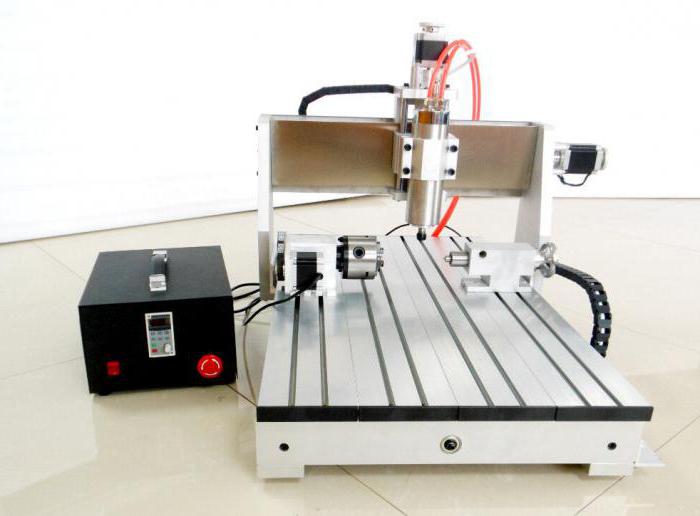

Compact and portable CNC router for metal

Industrial CNC milling machine for metal is producedexpensive at large dimensions. Compact models acquire small organizations for the implementation of single lots. Demand for such installations is observed in the service area. Acquire desktop models of production with unique equipment, which spare parts are not available for sale. Manufacture of such nodes by third-party organizations exceeds the cost of the machine itself.

Reasons for the popularity of automated machines

CNC milling machine for metal is able to produceproducts of high quality, comparable with the requirements of engineering industries. The construction of the equipment allows processing of materials from plastic, wood. Versatility in application and low cost have made axial systems the most popular.

The cutting process is carried out in automaticcycle. Mini-milling machine with CNC for metal is connected to PC, laptop via USB interface. Only a network of 220 volts is required, which is located practically in any production room. When repairing a car in the garage it turns out to make the simplest details.

Complex forms of final products require the creationcompetent drawing in 3D-format, which is rather difficult to perform in case of lack of qualification. The graphic file is converted with the help of common and free programs into G-codes. Already ready commands are loaded into the controller memory.

What can I do on the machine?

Mini-milling machine with CNC for metal performs the following operations:

- Milling.

- Engraving.

- Drilling.

- Movement along the bends of the workpiece.

- Open the material.

CNC milling cutter for metal makes it possible to manufacturenot only necessary for repair parts, but also to implement shaped models of limited dimensions. Long billets are processed not with desktop versions of equipment, but using portal structures.

Depending on the design, the installation withThe CNC system allows the processing of cylindrical workpieces to be clamped into the spindle assembly. The tool remains fixed in this embodiment, the table moves along two coordinates. Flat parts are placed in the clamps on a fixed base.

Package Contents

Everyone knows a 3D printer that creates three-dimensionaldetails by gluing small pieces. He has several axes and a knot that separates the working substance. The CNC milling cutter works on the same principle. The price of the machine depends on the following components:

- Rigidity of the structure. Under the treatment of hard alloys it is necessary to provide a strong base, the main pressure is applied to it. Axial guides and bearings are responsible for compensation of retroactivity. The cutting technology is selected to be optimal, so that the main components do not wear out.

- The purpose of the machine is universal, but it canbe tailored to the specific needs. The additional equipment is a chip scraper, coolant coolant installation. A monitor may not be used to display information. But so it will be easier and quicker for the installer to repair and adjust the machine.

- The type of the spindle unit makes a significant contribution to theprice increase. According to the experience of the masters, it is recommended not to save on an important element. Thus, there are periodic problems with the accuracy of the brand KRESS FHE / FE.

- Axial movements are carried out by stepping motors.

The main points when choosing a machine

Price list for CNC milling machine for metal can reachseveral hundred thousand rubles. These include extended versions that have 5 axes. Two additional coordinates are used for spatial displacement of the spindle. This solution allows you to manufacture complex parts in one operation.

The simplest models of low rigidity and limitedfunctionality are sold for only a few thousand rubles. With their help, quickly made parts of soft metal. The processing speed also depends on the type of tool. The following parameters are taken into account:

- noise of rotation of the spindle;

- interchangeability of spare parts;

- type of mechanisms;

- simplicity of installation and commissioning;

- weight of equipment;

- power consumption;

- number of coordinate axes;

- The possibility of modernization in the future.

Additional Features

Bench top milling machine for metalThe economy variant is connected to the PC via the LPT port. The process control is self-contained, it does not require operator intervention. A forced stop is added to the processing program during errors or on demand of the technology.

The cutting process is translated into 3D graphics by the programLinuxCNC, designed to fully control and display the technological process of CNC machines. Monitoring of the status of the installation nodes takes place in real time. The application interface is not inferior to the industrial versions of the software.

</ p>