Casting in shell molds: the basic operations of making molds

Casting in shell molds is also called shell casting. And abroad such a method of work is called Shell.

general information

In the modern industrial industry,many different ways of casting. In addition to shell, also casting on investment models, as well as in metal forms and several other methods is also used. A common advantage of such methods of casting, when compared with sand molds, is that they enable us to obtain more accurate final materials in terms of their shapes and sizes. In addition, the amount of roughness on the surface of such products decreases. In more rare cases, it does happen that there is no need for subsequent machining after melting. In addition, the use of casting in shell molds and other methods contributes to the fact that it is possible to mechanize this process as much as possible, thereby increasing its automation. And this, of course, greatly increases the productivity of any industrial facility.

Casing casting

Speaking specifically about this method, heIt was first introduced in factories back in 1953. At the present time, the method is used quite widely. It is casting in shell molds, for example, most of the parts for the Kirovets tractor are manufactured. All the details that are produced by this method, are obtained the highest quality of steel or cast iron. By shell casting is meant a method in which the final result of the casting has a shape consisting of two sand-resin shells. This method of manufacturing parts is also used only in cases where it is necessary to create a part with small or medium dimensions, but with high accuracy. Examples of the application of this casting method can be engine parts or thin-walled castings.

The essence of the method

With this method of work, you canget different parts for fans, motors, pumps or textile machines. However, the maximum length of the resulting product can not exceed 1 meter, and it can not be more than 200 kg.

The essence of casting in shell molds is basedon certain properties of thermosetting resins, which are part of sand-resin mixtures. The advantage due to which such components are used is that these resins have the property to harden and irretrievably harden if treated with a temperature of 200-250 degrees Celsius.

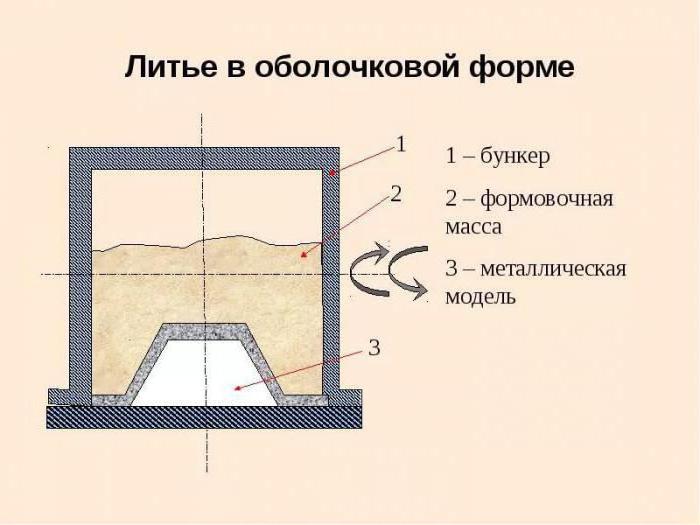

Manufacturing of a shell mold for casting

In order to make a shape for the subsequentcasting, it is necessary to have fine-grained quartz sand, which comes with the addition of a thermosetting resin, which is its binding element for obtaining a full shell shape. These materials, in particular, the resin is selected because it passes through a certain temperature barrier and hardens. The manufacturing process is as follows. First, the resin is heated to 140-160 degrees Celsius. Under the influence of such an environment, it turns into a liquid sticky mass that completely envelops the quartz sand shape.

The field of application of casting in shell forms is quite wide, and therefore the very process of making molds is brought to automatic or automated.

After the form is completely coveredresin, the temperature is increased to 200-250 degrees Celsius. This temperature threshold is sufficient to make the adhesive mass irreversibly harden and form a shape. Further, when the process of casting parts begins, that is, when the molten metal enters the mold, the temperature in it reaches about 600 degrees. This regime is sufficient for the resin not to melt, but burned, leaving pores on the very form that facilitate the escape of gases.

Advantages and disadvantages of casting in shell molds

Like any other manufacturing process, this onehas its positive and negative qualities. If we compare this method of casting, for example, with casting into ordinary sand molds, then we can distinguish several of the following advantages:

- The first and rather significant difference isaccuracy class, which is 7-9. In addition, the surface cleanliness of the resulting part improves to 3-6. In addition, the allowances that are allowed for subsequent machining of the resulting part after casting are reduced.

- One of the big pluses is a significant reduction in labor costs for making castings.

- This method of casting allows you to reduce the consumption of molding materials, as well as the amount of metal due to the fact that the size of the sprue canals decreases.

- Significantly reduces the amount of rejection at the output.

However, there are some disadvantages of casting in shell molds. These include:

- The service life of the shell mold is 1 cast.

- The cost of the molding mixture is quite high.

- High percentage of harmful gases.

The process of forming the body

The process of forming the hull is carried out in six stages:

- The first step is the process of pouring the mixture intoa hot model of metal, and also the process of its aging, which lasts for several tens of seconds until a thin, strong crust is formed around the part. Most of the models are made of cast iron, and their heating is carried out to 230-315 degrees.

- After this, it is necessary to carry out the operation onremoval of excess molding mixture. The thickness of the cake should be between 10 and 20 mm. It depends on the time the mixture is on the model, and also on the temperature.

- After this, it is necessary to transfer the model platetogether with the form in the furnace, where they will be until the end of the hardening process. At the end of this procedure, the strength of the shell should be from 2.4 to 3.1 MPa.

- After removal from the furnace, the hardened shell is displaced from the plate. For this procedure, use a special pusher.

- After that, two or more models are fastened togetherwith each other by means of a clamp or by gluing. Data forms can be used for casting in shell forms or simply stored. Shelf life is almost unlimited.

- Before starting the casting process in the finished form, a shot is placed in them, which helps to prevent or destroy the mold during further pouring.

Casting Details

It is worth starting with the fact that the typical tolerances thatallowed in the manufacture of equipment can be 0.5 mm. Surface roughness is allowed in the range from 0.3 to 0.4 μm. Such limits are argued by the fact that fine sand is used. Also worth noting: the use of resin significantly contributes to the fact that the surface will be very smooth.

Volumes of production

In order to engage in the production of suchforms and details, it is necessary to attend to the installation of the model-mold. The time required for installation is less than a week. After the completion of the installation, the quantity of produced products can reach from 5 to 50 pieces per hour. Such volumes of production per hour are quite real, but for this it is necessary to prepare the casting process accordingly. The main materials that will be required for casting are cast iron, aluminum, copper, and also alloys of these kinds of metals. Another necessary material will be an alloy using aluminum and magnesium.

</ p>