Productivity of bulldozers. Calculating the productivity of the bulldozer

In the development of excavations, excavations and embankmentsit is advisable to use bulldozer equipment if the average range of longitudinal or transverse carriage does not exceed 100 meters. To choose the most optimal model of special equipment, it is necessary to compare the performance of bulldozers with different traction class and different types of working equipment.

The most promising arecaterpillar engine. Technique on a pneumatic wheel drive is in demand less. When calculating the productivity of an earth-moving machine, it is necessary to take into account the conditions of the terrain, the nature of the work and other factors.

Basic information about bulldozers

Bulldozer - earth-moving machine forlayered development and transportation of soil, developed on the basis of a caterpillar or pneumatic wheeled tractor with interchangeable attachments - a blade (a flat shield with lateral openings), a frame and a control mechanism.

The control mechanism of the blade can be cable-block and hydraulic. The second type of control is more productive, since it allows forcing the blade to be forced into the ground.

Traction class of cars

With the help of bulldozers, up to 40% of allexcavation at the construction site. They are most effective at an average range of longitudinal and transverse carriage from 100 to 150 meters. When equipping machines with special scoops, the effective range of the sandy soil is increased to 200 meters.

- Light, pulling force of which does not exceed 60 kN. They are used during preparatory, agricultural and auxiliary works.

- Medium, with a pulling force of 100-150 kN. Used to develop 1-3 groups of soil with preliminary loosening.

- Heavy, pulling force of which exceeds 250 kN. They are used in the development of dense and hard rocks.

Bulldozers are used in conjunction with otherearth-moving machines. They can be used as pushers for self-propelled and trailed scrapers. Typically, a bulldozer equipment set includes a ramming machine and a ripper.

Factors affecting performance

Counting the productivity of bulldozers,It is necessary to take into account the physical and mechanical characteristics of the developed land massif, as well as local conditions. The basic physicomechanical characteristics of the soil include:

- granulometric composition - the ratio of the particle size of the soil by mass;

- density - the mass of the soil in a unit of its volume;

- porosity - the number of voids between grains, expressed in percentages by weight;

- the plasticity number is the humidity range in which the soil has plastic properties and does not go into a fluid state;

- swelling - the ability of the land mass to increase in volume when waterlogged;

- angle of internal friction - resistance of soil particles to the cut.

To local conditions affectingthe productivity of bulldozers, include the nature of the relief and the technological features of the construction site. On a flat and straight section with a minimum range of transverse draft, the speed of work is much higher than in a hilly terrain.

Calculating the productivity of bulldozers

The performance of the bulldozer depends on the type of work performed. This can be earth-moving or planning work. In the first case, the productivity is expressed in m3/ h, in the second - m2/ h. More details on earth-moving works.

Operational productivity is determinedthe volume of land mass that special machinery can develop and move per unit of time, that is, in one hour. Calculation of the bulldozer's productivity is carried out according to the formula

- ky - the effect of the slope of the ground. During operation on gradients from 5-15% the value increases from 1.35 to 2.25; when developing the ground on the rise, the coefficient decreases from 0.67 to 0.4;

- kat - value that takes into account the time of use of the machine (kat = 0.8-0.9);

- kMr. - coefficient of filling the geometric volume of the prism of drawing (kMr. = 0.85-1.05).

To calculate the performance, it is also necessary to know the volume of the prism of the drawing (Vgr) and the duration of the working cycle of the machine (Tcentners).

Calculation of the prism of the drawing

A characteristic feature of the machine is the fact that the bucket of the bulldozer moves the soil in the so-called drawing form. The volume of the prism is calculated from the formula

Duration of cycle

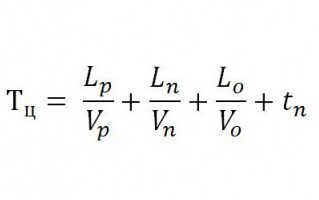

To calculate the duration of the operating cycle,There is a time that a tractor-bulldozer will spend on the development of one layer of soil, it is necessary to understand that the entire length of the longitudinal or transverse carriage is divided into several segments. The duration itself is calculated by the formula

Bulldozer productivity with a wedge work pattern

The application of a wedge pattern of a soil set is possibleOnly with those machines that are equipped with a hydraulic blade control mechanism. Such, for example, is the bulldozer "Shantui SD32". A distinctive feature of this principle of soil development is the fact that the cutting force gradually decreases as the prism of the drawing increases.

Thickness of earth shavings

Most often resort to the second option, but inIn this case, some of the land is "lost" in the lateral ridges (the worse is the "Shantui" bulldozer). To compensate for these losses, the machine along the entire path of movement must cut off the "shavings", which is calculated by the formula

Impact of blade type on performance

Depending on the characteristics of the soil, as well as fromset tasks before the bulldozer, it is advisable to use certain types of dumps. This will shorten the period of production, as well as increase the efficiency of special equipment.

Any machine, including the Komatsu bulldozer of Japanese manufacture, is equipped with a replaceable blade. Among the main types of working equipment is:

- recultivation subspecies, which is used to remove the upper fertile soil layer, chernozem;

- a variety for the movement of coal and chips - is used in the development of minerals, has a hemispherical shape and a hydroisperoscope;

- "Peat" variety has a reduced height, but an increased length and is used to enrich the agricultural fields;

- dumps for the preparation of the site - brush cutters and trimmers, which are equipped with teeth, are produced in V-shaped and designed to clear the terrain from trees and shrubs.

The most progressive (in terms of opportunitiesinstallation of various working equipment) is a Japanese Komatsu bulldozer. All models of special equipment can be equipped with any of the presented dumps, which gives them high functionality and makes universal machines for the construction site.

Calculation of bulldozer performance is necessaryconduct to reduce the cost of excavation. On the basis of the data obtained, it is possible to select the most suitable for the work of special equipment, shorten the period of production and save a lot of money.

</ p>