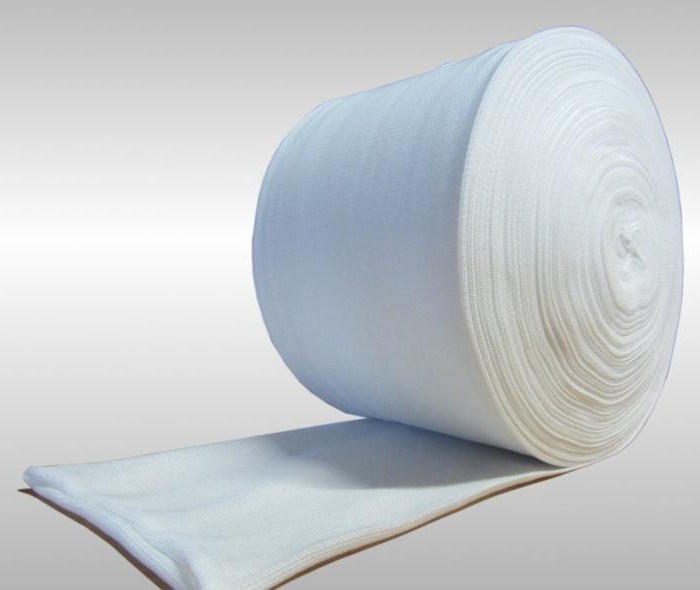

Filter hose: materials and application features

Filter hose belongs to the categoryequipment of a universal type used for air purification, the temperature of which does not exceed 260 degrees. It is an effective dust collector and is made, as a rule, to order taking into account the operation features and the sizes of replaceable elements. The structure can be ellipse or round in shape and equipped with a ring made of rubber, spring and wire.

Filter hose: scope

There are many technological processes that require the use of such elements:

- refining of oil and production of metallurgical products;

- sawing and other types of wood processing;

- ventilation of cement silo;

- manufacturing of cement;

- grinding and metal processing;

- tobacco production;

- production of carbon black and plastics.

Materials

As materials for the manufacture of hosespolyester, fabric, polypropylene, fiberglass are used. There are products supplemented with electrically conductive fibers, antistatic coating, and also designed for high temperatures and having water repellent characteristics. The outer layer can have a mesh or nylon fleece coating. Sleeves having a calendered surface have become fairly widespread. Due to their use, the fine fibers are prevented from falling into the filtrate. The process of calendering the fabric consists in rolling through rolls heated to a certain temperature, and then sintering the fibers.

Features of operation

The replaceable part of the filter is subject to a constantwear and heavy loads, which necessitates regular replacement. In addition to removal of old elements, timely cleaning of bag filters, branch pipes and the hopper from accumulated contamination is required and a subsequent system check. The required level of efficiency of aspiration structures is achieved only if the new hoses are systematically installed.

There are several basic types thatdiffer in the specific operation. A filter hose that is used in a high-temperature environment and to catch explosive dust has become quite common. The basis of the construction is the body, which has two chambers, valve sections and frame filtration elements. The air enters the chamber through the branch pipe and passes through a filter, on the surface of which there is dust. After cleaning, the air is discharged into the special chamber through the open hose elements.

Manufacturing

The production process is carried out on the newestequipment with the use of high-quality cloths, including materials of different conductive properties. The filter hose, designed to catch dust with increased explosiveness, is supplemented by valves with a special membrane. In this case, a separate installation of the starting equipment is required in the allocated room. Removal of collected dust can be made with different regularities depending on the operating conditions. With the help of sluice gates, the discharge section is sealed when dust collection is necessary on the installed filter. Other types of sealing devices are also used.

Certain types of filters are supplementedautomatic systems that allow controlling the mechanisms for unloading dust from several filters simultaneously and preventing damage to the structure as a result of exposure to high-temperature gases. Such systems are used to transfer data for the subsequent observation and control of the cleaning mechanism.

</ p>