Galvanized ventilation pipe (GOST)

Recently it has become quite commonGalvanized ventilation pipe, which has a high plasticity and has anticorrosive properties. Such products can be used in a variety of conditions, but it is important to choose them correctly. As a coating, they use aluminum zinc, consisting of 5% aluminum and 95% zinc.

Flexible ducts have manyvarieties, however they are manufactured according to state standards 14918-80 and are distinguished by a high degree of chemical resistance. On sale it is possible to meet pipes for ventilation systems, which are characterized by ultra-high resistance to corrosion, as well as temperature differences, in this case GOST 5632-72 is used in the production process.

Technical characteristics and GOST

Galvanized ventilation pipe can haverectangular or round section, the seam is seam or welded, and its direction - direct or directed along a spiral. There are different products that can be classified for tightness. But to operate the air duct is possible, if the temperature of the environment does not rise above 80 ° C. The ventilating zinc-plated pipe is 100 mm - this is the product, which starts a ruler of the diameters. The largest diameter is the limit of 1250 mm. The thickness of the sheet used can vary from 0.5 to 1.25 mm, while the minimum length of the product itself can be 3 m, but the maximum length is 25 meters. Correspond to these products sanitary norms and regulations 2.04.05-91; 3.05.01-85.

Galvanized ventilation pipe canUsed to transport air with a humidity of 60% or less, the temperature should not rise above 80 ° C. If the product is operated under these conditions, then in the production process a sheet of steel is used, which is manufactured by the method of cold rolling. Its thickness should be equal to the limit of 0.5 to 1 mm, while the material must comply with state standards 14918-80. To move hotter air, the temperature of which will reach 500 ° C, special products should be used that are suitable for gas transportation.

Thickness according to sanitary norms and rules

Galvanized ventilation pipe 100 mm isproduct and its diameter, but this characteristic is not the only one that determines the characteristics of such systems. It is important to know also about the thickness, which is regulated by sanitary norms and rules 11-33-75; 41-01-2003. If the air duct diameter changes to within 315 mm, then the thickness of the used sheet will be 0.5 mm. If the first parameter will vary from 350 to 800 mm, then the product should have walls with a thickness of 0.7 mm; when the diameter increases to 900-1250 mm, the wall thickness will be 0.9 mm. The thickness of the walls will be 1.2 mm, if the diameter is 1400-1600 mm.

Fire resistance limit

Galvanized ventilation pipe may possessa certain fire resistance limit, this characteristic determines how much time the product can last from the start of heating. This parameter is indicated in minutes, it can be found on the duct. For pipes that are used in ventilation systems of high-rise buildings, the fire resistance limit is 90 minutes, such designs are installed on the ceiling.

If we are talking about corridor walls, then the limitto make 30 minutes. Such air ducts belong to the zero class of fire resistance, whereas for today five classes are known. From zero to fifth degree, the fire hazard increases. The pipe can be additionally protected by fireproof composition. You can do this yourself, but beforehand, the consumer needs to clean the outer surfaces of the product.

Classification of air ducts

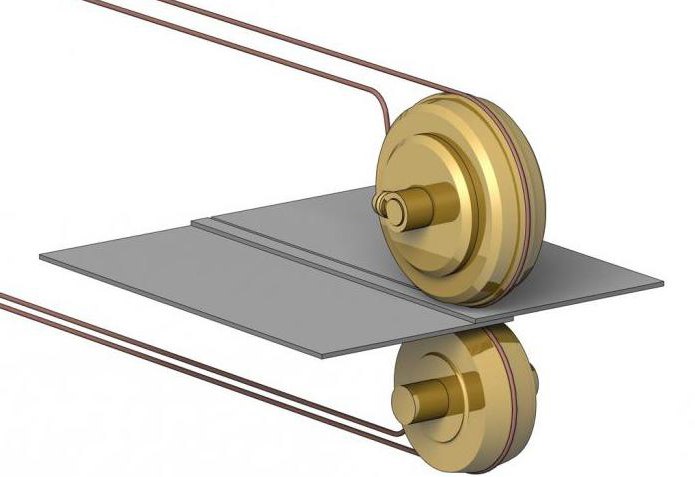

The air ducts described can have a rectangularor a circular section. The products, which were mentioned last, are divided into spiral-lock and stitched. Pipes with a circular cross-section are more advantageous than rectangular tubes. Weigh round much less, their tightness is higher, and installation of such systems can be simplified.

Rectangle products are interconnectedflanges at installation, however the technology is used and without flanges. The area of use of rectangular pipes is residential buildings, offices, schools and production facilities. Round ducts are much cheaper than rectangular ducts, the price for them is 35% lower. Air distribution in such products occurs evenly, and noise-absorbing properties are higher.

Features of insulated, spiral-wound and stitched products

In air-insulated pipes, the air temperaturedoes not fall, this eliminates the occurrence of condensation on the walls, which could damage the material. Galvanized pipes work quite noisily, and the presence of a thermal insulation layer performs noise isolation functions. Such a layer can be made of mineral fiber, felt, polyurethane, and also a foam elastomer.

Galvanized ventilation pipe (125)Spiral is made from twisted tape, which is obtained by a spiral method, this increases the strength and rigidity. In length, such products are usually equal to 3 m. In navigable pipes there are fewer joints, which means that the system has a higher tightness. Straight pipes are cheaper compared to spiral pipes, because for their manufacture there is no need to prepare a sheet of galvanized steel. The length of the longitudinal pipe is usually 125 m, as a rule, they are purchased for installation on the street.

The cost of round air ducts made of galvanized steel, depending on the diameter

Galvanized ventilation pipe 200 mm isthe most expensive item, pay for which will have 755 rubles. If the diameter increases to 1250 mm, the price will be 7,500 rubles. a piece. For products with the smallest diameter of 100 mm, you will have to pay 400 rubles. The averaged index with a diameter of 500 mm will cost the consumer 2,800 rubles.

</ p>