Sandwich panels: characteristics and application

Constructions consisting of three or more layersrigid material, are called "sandwich panels". Their characteristics indicate reliability. As a rule, the outer layers are protective and bearing, and internal represent variations of insulation materials, depending on the purpose of the building. Sandwich panels are increasingly replacing other types of structures. Their popularity is due to their low weight and ease of installation. No modern shopping center can do without them. Now the market has a large selection of insulation materials, which allows you to provide the necessary thermal conductivity, noise insulation, moisture resistance.

Why use profitable?

Why do more people choosesandwich panels? The characteristics of concrete and bricks indicate the great reliability of traditional materials, but practically all other parameters of the sandwich panel in front. Their low weight and durability allow to reduce the cost of transportation of materials, do without the use of lifting mechanisms during installation. There is no need for a solid, powerful foundation.

When building shopping centers and shopsthe speed of construction is an important factor, because the faster construction is completed, the faster the costs will start to pay off. Sandwich panels, whose characteristics make it possible to simplify installation as much as possible, are attached to metal, concrete and wooden frames. For small buildings (like car repair shops) they produce ready-made sets of carcass and panels, they can only be assembled in the right order. Such structures are quickly and easily disassembled and repaired.

Kinds

The material is classified according toseveral parameters. Isolate wall and roofing sandwich panels. The technical characteristics of the first are such that they can be used as vertical and inclined enclosing structures, and also as overlaps between floors. Roofing is used for pitched roofs. Both those and other constructions are used in the construction of industrial, warehouse, public, commercial buildings and low-rise residential buildings.

Sandwich panels differ in appearanceheat-insulating material. There are with insulation of mineral wool, polyurethane foam, expanded polystyrene, fiberglass and their combination. Each species is applied depending on the purpose of the building.

Protective layers

The outer layers can be made from different materials. Basically made of metal (thin-gauge stainless steel). Also there are options with plasterboard, fiberboard, DSP, PVC and paper.

Panels with paper are used mainly as a heater, paper is an additional protective material for insulation.

Simple sandwich panels, technicalthe characteristics of which are interesting only in terms of thermal insulation, are manufactured directly on the construction site, this greatly simplifies the installation process. Pre-assembly allows more rational use of time. While the frame is being erected, a wall fence is already being prepared on the ground.

The outer layers are covered with different polymers,which increase the anti-corrosion properties. The type of coverage depends on the cost of the sandwich panel. Technical characteristics indicate resistance to mechanical stress, sunlight and temperature changes.

Mounting Features

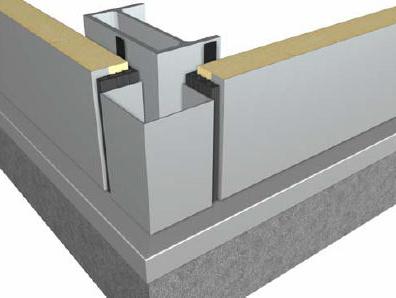

Installation of sandwich panels is extremely simple and reducesin just a few basic ways. The first and most common is the groove-groove connection. In this case, at the fixing point, one of the panels is thinner on the whole side, while the other has a groove.

When connected to the frame grooves are left and fastened to wooden, metal or concrete racks.

The most reliable lock is Z-lock ("double shutter"). Two inclined spikes of one panel mate with the groove of the other.

Secret fastening is used for facingsandwich panels. The characteristics allow you not to think about the tightness of the seams and how to hide the fastening elements that spoil the appearance of the facade. First, the panel is fixed with screws to the wall, and then the hats are closed with the next panel.

Roof-lock is a lock for roofing, it is built on the principle of overlap.

There are also eccentric locks, with which the panels are pulled together. Such fastening is used mainly for refrigerators.

Wall panels

As enclosing structures, increasinglyapply sandwich panels wall. Their characteristics are represented by thermal insulation and protective function. The most common type is a panel with a heater between two metal sheets. Such designs can be used anywhere in Russia, depending on the climate, the thickness and type of insulation change.

To factory panels it is necessarily enclosedinstallation instructions. With the correct assembly of the design will last from 20-25 years and more. They meet the requirements for fire safety and do not cause harm to human health.

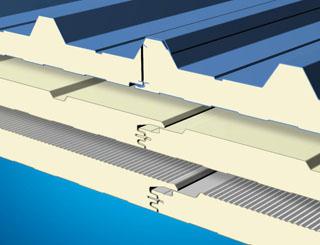

Roofing sandwich panels

Technical characteristics of such structuresUnique: they are convenient, quickly mounted and long-serving. The maximum length of the panels is 21 m, of course, for the transportation of such structures requires a range finder, but the speed of construction is significantly increased. Slightly weighs the roofing sandwich panel. The characteristics of the mass and dimensions allow the use of lightweight load-bearing structures. The roof slope should be at least 5% in the absence of cross connections and hatches for light. Otherwise, the slope should be at least 7%.

When installing a roofing sandwich panel, the following rules must be observed to avoid injuries and damage to the structures themselves:

- At a wind speed of more than 9 m / s, installation can not be carried out. The larger the panel, the higher its sail, it can easily carry a person with it.

- It is also not possible to install during precipitation (snow, rain, fog).

- The installation process should be accompanied by normal lighting.

- Sealing of longitudinal joints should be made at a temperature not less than +4 aboutFROM.

Slopes

The materials in question are already used inquality of enclosing structures and roofing. Now there were also sandwich panels for slopes. Their characteristics are not very different from their predecessors: they are very convenient and practical, they do not require additional insulation, finish, installation is not difficult, and the service life is not less than other slope variants. Sandwich panels with plastic as a protective layer are not afraid of water, unlike plasterboard, do not fade for a long time in the sun, they do not puncture, they do not attract dirt, like plaster.

Thanks to the adjusted production at prices, sandwich panels have become available. They will not displace other building materials, but they have taken their niche firmly.

</ p>