Saw tape - a necessary tool in the household

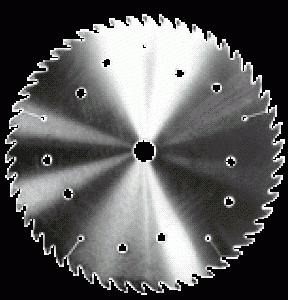

Saw tape is an essential tool for sawing wood materials and metal. It is used both in industrial production and for individual needs.

Saw tape is produced in several types(wide, narrow, wood, metal). Often, specialists working in the woodworking industry, re-sharpen them for use on special machines. This procedure significantly increases the operating life of the wide cutting surface. A narrow web can not be subjected to such a procedure, so it is used until complete wear. Precise routing of the saw teeth guarantees a high productivity and excellent cut quality. The band saw has an increased resistance to overheating, since additional heat treatment allows it to produce straight-line propyl. The cutting blade has a convenient sequence of straight, right and left teeth that fit well with the grinding equipment.

Since in different spheresonly products made of wood, but also of more durable materials, the industry produces also band saws for metal. Gradual hardening gives them increased hardness. They are used for cutting blanks of plastics, organic glass and metals.

Many firms produce medium-alloyed sawsbecome. As the alloying element is used tungsten, molybdenum, chromium or vanadium. Saw tape for metal from this steel has a hardened edge of the working cloth (by 0.6-0.8 cm of tooth height). Such a fabric has a capacity several times greater than that of carbon steel. Molybdenum band saw is of three types: for high-speed, contour and straight cutting. Cutting cloths are divided into 3 types: for magnesium and aluminum alloys, for blanks of cast iron, for alloy steel.

Band saw is used on specialmachines designed for metalworking. Its use in this industry is the most promising type of resource-saving technologies. Continuity of cutting and narrowness of the cut determine the main advantages of this cutting method: low energy consumption, minimal amount of waste (chips), obtaining precise blanks, versatility of the processing method.

</ p>