Sheathing of the house with block house. Block house under the log

The most popular recently becomesmaterial for the design of facades and interiors under the name "block house". These are panels with a semicircular profile that simulate a round log. This finishing material is used for facing various structures and surfaces. The sheathing of the house with block house gives it the appearance of a wooden frame. You can finish them in all seasons. Due to its qualities and technical characteristics, it in many respects surpasses other finishing materials.

Application of block house

Block house is used for interior and exterior decoration of houses and structures. They are facing the surface:

- wireframe;

- wooden;

- concrete:

- monolithic;

- brick.

Very easy and convenient to carry out their finishingthe work of prefabricated frame structures, and also to use it for the restoration of structures, since the board does not exert a large load on the foundation.

These decorative panels are made of natural wood, metal, vinyl. Depending on the material of manufacture, each kind has its own properties and advantages.

Wooden block house

Its popularity has been gained by the wooden block housedue to high quality and aesthetic performance. It is difficult to distinguish it from round logs or log masonry. For the production of wooden block house, well dried and treated with antiseptic wood of cedar, larch, pine or spruce. Products from coniferous trees have a high waterproofing, so they can be used for finishing baths and saunas.

Material (depending on the quality) is dividedto four classes (A, B, C, "Extra"). Interior decoration is carried out by products A or "Extra", the cladding of the house by the blockhouse on the outside is carried out by category B or C.

The house or other structure will have a beautiful view,If the natural wood is combined with a brick or stone. The wooden block house is air-permeable, fire-resistant, resistant to atmospheric precipitation and temperature changes, natural and ecological, protected from damage by mold, fungus and various rodents.

Vinyl Block House

This type of product is a benta semicircle bar that simulates a bar or beam. Unfortunately, it is not very possible to display the accuracy of wood texture, and one can consider their inconsistency near. Vinyl block house under the log is used for interior decoration of premises and facades. It has the following advantages:

- waterproof;

- resistant to ultraviolet light;

- fireproof;

- does not need special care:

- convenient and easy to assemble.

Metal block house

The metal block house is also called metal scoring, which simulates a round log. Such a finishing material is made from galvanized steel with a multi-layered protection system.

Like the vinyl material, it does not have a perfect imitation of wood. However, the paneling of the house with a metal block house looks elegant.

This type of product has several advantages:

- environmentally friendly material;

- resistant to temperature changes;

- long-lived;

- is durable;

- fireproof;

- not exposed to corrosion;

- easy to install.

Dimensions

The dimension of this building material is influenced byon the field of application. Narrow products are used for interior decorations, as they visually increase the room. If the building is large, wide panels should be used, which will contribute to an expressive visual effect. The exterior decoration of the buildings will provide him with reliable protection. Sheathing of the house with block-house (the price depends on the area), made by a wide board, will cost more.

- The wooden block house has dimensions from 2 to 6 m in length. The width for the exterior decoration is 14-19.5 cm, for the inner - 9-13.5. The thickness is from 2 to 4 cm.

- Vinyl board has a length of 3 to 4 m, a width of 24-25 cm, a thickness of 1 mm or more.

- Metal block house dimensions are always standard: length from 0.5 to 6 m, width 21 cm, thickness 0.5 mm.

Installation of the block house

You can install the products yourself orto attract specialists. It is not necessary to have special skills, but it is necessary to know a few rules so that the paneling of the house with block house is qualitative. Most importantly - take your time. Before installing the finishing material, make sure that the surface is clean and dry. For its alignment, the crate is made of wooden bars with a section of 50x30 mm with a step distance of 60 cm, which is fixed with screws to the wall.

On the surface of brick, concrete frameis made of metal profiles. Then the block house is fixed. You can install it vertically or horizontally. The panels are connected by the spike-groove method. At the joints, the wooden panels are filed under an angle of 45 degrees. It should be noted that in order to avoid the accumulation of water in the grooves and to prevent the possibility of rotting the panels, it is necessary to mount them with a spike upwards from the bottom of the building.

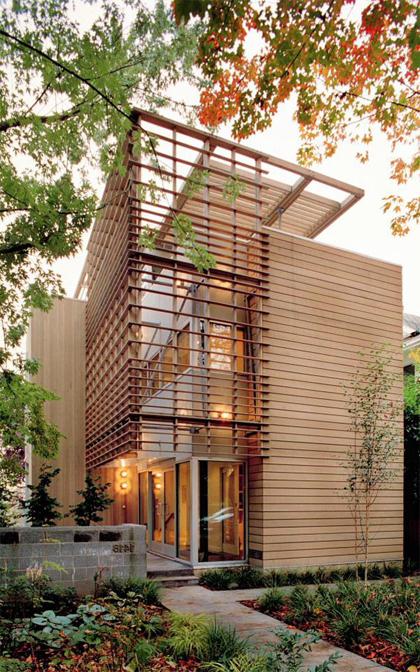

Sheathing of the house with block house provides layinghydro and thermal insulation. Lay the layers of these materials between the work surface and the crate. Metal siding to the crate is fixed by brackets. The panels of the block house can be fixed by various methods. Everything depends on its thickness. Sheathing of the house with block house, the photo presented below about it shows, it looks very elegant.

Scheme of installation by block house of a wooden house

Installation of products on a wooden house is carried out according to the following scheme:

- Surface.

- Waterproofing.

- Frame (crate).

- Heater.

- Protective film.

- The second frame.

- Block house.

Features of installation of the block house in the interior

Surface finish at plus temperatures should be carried out in a well-ventilated area.

The interior decoration should be carried out with narrow panels.

Products used in the interior do not need additional processing.

How to choose a quality block house

Choosing the finishing material, first of allIt is necessary to determine where it will be applied. It should be remembered that with interior decoration, narrow panels are used, whose length does not exceed 6 m, width 9 cm, thickness 2 cm.

The exterior decoration of buildings is performed by wideboards, their width is 19 cm and thickness is 3.6 cm. The choice of panel in this case depends on the size of the buildings. Do not forget about the types of wood from which the material is made. Coniferous rocks are best used for finishing living quarters. Conducting the lining of baths and saunas with pine or spruce panels is not worth it, since they contain tar, which when heated is released and leave sticky dark spots.

When choosing a block house board, it is necessary to turnspecial attention is paid to the conformity of this material to the class, and to the location of annual rings in the wood. If the distance between them is small, this means that the boards are of high strength. There are three classes of wooden block house. To each of them specific requirements on color, presence of knots, chipped, blue and others are put forward. In addition to Class A, which is of the highest quality, there is the category "Extra" - the ideal wood. It is very expensive and very rare in the market.

Not the last place in the choice of material takessuch point, as storage. This affects the quality of installation and operation. Products should be stored in a dry unheated room, on pallets in a special manufacturer's packaging.

</ p>