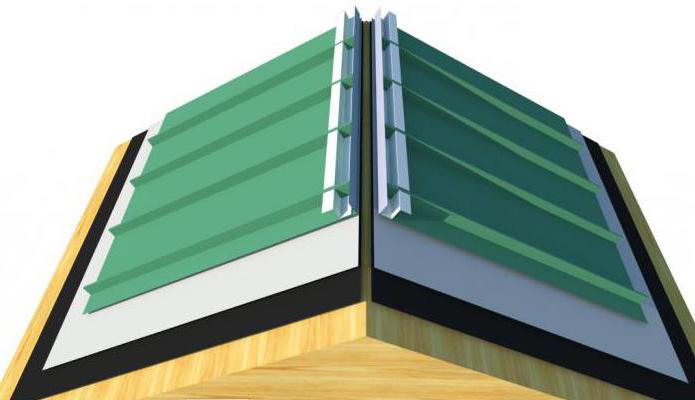

Scheme of metal tile fastening. Dimensions of screws, accessories, technology

Metal can be called truly uniquebuilding material that differs not only in durability, but also in attractive appearance, and high strength, which is manifested throughout the life of the plant. It is made of steel sheets, which are coated with polymer in the process. Special stamping made it possible for the material to look as if natural shingles were used in the work. If the sheets are fastened by technology, the joints of the sheets along the waves and rows will be invisible. Use this covering material on pitched roofs with an inclination angle of 14 ° or more. Together with the metal tile it is necessary to purchase roofing slats, namely: end, skate and cornice. In no way do without flat sheets with the same coating that has a metal tile. With the help of these additional elements you can form aprons and other nodes of the roof.

Recommendations for fastening metal

Before you fix the metal, you mustmore familiar with the technology of work. Use for this purpose self-tapping screws, the most common sizes of which are the following: 4.8x35 or 4.8x28 mm. Fasteners must have a rubber gasket. In order to exclude the allocation of self-tapping screws on the surface, their hats are painted in the color of the covering material. When using a screwdriver, the torque must be limited. After the pressing is completed, the rubber gasket should only be slightly tightened. With insufficient torque, you will not be able to achieve the desired degree of sealing of the hole. Otherwise, there is a risk of turning the screw, which will cause the fasteners to loosen. Among other things, in this case the gasket will be deformed, which will shorten the life of the coating.

Tips of the master

If you are thinking about how to strengthenmetal tile, we must remember that the samorez is strictly perpendicular. There must be an angle of 90 ° between the surface of the lathing and the fixture. Fastening at installation of sheet on a lath is screwed in a place of a bend of a wave. The bottom sheet to the starting plate is fixed with the pitch between the screws through the wave. Many novice masters are thinking about how to fix metal roofing at points of vertical overlap. In this case, you can not do without short self-screws, the length of the screw is 19 mm. This screw is set in the wave recession. On the perimeter of the roof system, screw the self-tapping screws into the deflections of the wave. The screws are staggered, they should be installed in each grate.

Features of fastening sheets

Self-tapping screws for metal will be expended ina certain amount. On a square meter of coverage, you will need 8 pieces. You should also remember the need to fix accessories, in this case you will need 3 pieces per linear meter on each side. The accessories are fixed in such a way that the screws are removed from each other by 350 mm. The scheme of fastening metal tiles with self-tapping screws assumes installation of fasteners in a transverse wave. When fastening along the slope, the fasteners must be installed in the upper comb, then it is located through one wave. When installing the fasteners, you must dispose of the formed chips and sawdust. For this purpose, a soft-nosed brush is suitable. If you do not do it in time, then the shavings will rust and ruin the appearance of the roof.

Features of metal tile fastening with multi-row laying

Fastening of metal tile with multi-row layingcan assume the presence of up to 4 sheets at the junction. If you superimpose in the same row, then there will be an offset. On the 10th cornice, it can reach 3 cm. This recommendation is correct for the case where the anticapillary groove is located on the right. The amount of displacement when turning should be about 2 mm. The scheme of fastening metal tiles with self-tapping screws when installing the second and subsequent cloths assumes their location to the left and right of the first one. Begin work is necessary on the side of the house where there are no bevels and there will be no need to cut sheets. The laying continues in the direction of abutment, which is formed by another ramp. You can move forward to the valley, which is located between the neighboring slopes.

Fastening of a metal tile at a triangular slope

The scheme for fixing the metal tile with screws will beslightly different if the roof slope has a triangular shape. In this case, the master performs the marking at the first stage, indicating the central part of the ramp, through which the axis is drawn. Further, the same axis should be marked on the web of roofing material. When laying, the axes must coincide. The sheet is fixed by one self-tapping screw, which is located at the top point. Then the work is done using the same technology as on rectangular roofs. When installing on triangular slopes in the valley area, the metal tile should be trimmed. For convenience, it is necessary to acquire an improvised tool, which is called a devil. The scheme for fixing the metal tile with self-tapping screws involves four boards, two of which must be parallel to each other, while the other two are perpendicular to them. The mount will be hinged, not rigid. The step between the inner surface of the left board and the outer side of the right should be 1100 mm, this parameter is equivalent to the working width of the covering material.

Additional nuances

For the work of metal, whichneeds to fit the sizes, fit on the devil. One side of the tool should be on the edge of the valley or the slope. When using this appliance, care should be taken to ensure that the horizontal boards are horizontal.

Laying scheme of metal with hidden fixing

If for the work you decide to usemetal roofing with concealed fastening, then for this it is necessary to take self-tapping zinc-coated roofing with a press-washer. Due to the fact that the fasteners on the surface will not be visible, you can use galvanized screws, which are not painted in the color of the roof. As the main difference is that there is no need to make through holes in the coating, because the screw will be installed in a special groove. Cloths between each other are fixed by hooks of mounting lugs and grooves, which are located on the edges. The place where the samorez will be located is hidden by the next canvas. On the surface there will be no fasteners and through holes. This way you will be able to create a sealed and more durable coating.

Fastening of metal roofing on the ridge and cornices

Self-tapping screws for metal are used for decorationcornice. Cloths should be mounted in such a way that the bottom cut extends beyond the edge of the bar by 50 mm. This will allow rainwater to enter the gutters. To prevent the lower cut from dangling, the edge of the lath should be 15mm thicker than the rest. Sometimes the lath of the abutment for the metal tile is installed on the cornice, it is necessary for drainage of water. On the cornice, the fixing points of the material are along the line of the cornice 8 cm below the punching. At the same self-tapping screws are installed through one wave. If the length of the top cut of the covering material is more than 30 cm from the extreme punching line above the top board of the lathing system, a sub-roof board must be installed, its thickness must be increased. The master must provide an air gap between the components of the bale system and its upper elements. The clearance should be 80 mm. The fastener is installed in the deflections of the wave of the extreme number of stamping, the distance between them will be equal to one wave. With a cutting length of more than 130 mm, the upper part should be further strengthened.

Fastening of metal tiles around obstacles

Plank of abutment for metal shouldinstalled around the pipe. It is attached to additional boards of the lathing, which makes it possible to obtain a continuous coating. To begin with, the master marks the lines of the abutment of the lower bar, which should be placed above the metal tile by 15 cm. Using the grinder, you must make the shtrobu along the line. It will enter the lower bar. The very first is going to the lower part of the apron, then you can go to the side parts. The lower apron is decorated with sheets of covering material, whereas the upper parts of the apron are installed from above. Elements are connected with each other according to the methodology that is adopted when carrying out tin work. To increase the tightness, use a silicone sealant.

Installation of components: installation of snow-holder

Accessories for metal tiles are presented tosale in a wide range. Among them you can find snow holders, the installation of which is carried out in several stages. In the holes formed in the mountings, you should install the pipe. The snow holder itself is fixed by screws to the crate in the lower part of the wave. And in order to ensure a dense fastening of snegozaderzhateley on metal, it is not necessary to organize a continuous crate. Places for fixing metal tiles with self-tapping screws have been disclosed above, but for successful completion of work it is important to know about the features of the installation of snow covers, the installation of which is carried out in several stages. The next step will be the installation of pipes snegozaderzhatelya, which can be located in a single row, while they are joined one into one. These elements should be located above the doors and windows, as well as at different levels of the multi-level roof system. If there is a sufficiently large length of the ramp, it may be necessary to install additional elements to hold the snow. Sometimes the tubular system of snow retention is improved by the method of installing a bar, which eliminates the drop of ice crumbs. This element is attached to the crate at the top of the wave.

Accessories and screws

Self-tapping roofing with a drill, the dimensions of whichcan be the most diverse, presented for sale in a wide range. Its dimensions can vary from 4.8x16 to 6.3x150 mm. These elements have an end in the form of a drill, which for installation does not provide for the pre-formation of holes. With their help, the joints can be sealed. Mounting is carried out to the metal frame of the roof. The thickness of the metal profile or sheet should not be more than 1.2 mm.

In addition to fasteners, you will have to purchase a skatesemicircular or straight, as well as narrow, which will depend on your preferences, stub skate or right bar. You will need a curtain rod, endowa, and also a rake. You need to buy an abutment and a smooth sheet, the last of which is used for finishing parapets and pipes.

</ p>