How to choose a laser engraver for your home? Tips and feedback about the manufacturers

Performing artistic engraving until recentlytime extended only to specialized spheres of production and decorative design. Today, thanks to the development of a segment of compact and at the same time efficient laser engravers, anyone who does not leave home can join this amazing lesson. True, the variety of devices on the market can make the choice of a beginner difficult. To get the best laser engraver for your home for specific needs, you should have an idea of the device's design and basic operating parameters. Also, a small review of the manufacturers will help you to orient yourself in a wide range of proposals.

Varieties of engravers

First of all, the general direction is determinedwork with the device. Choosing a model for a specific material is not practical, because in the future, it may be necessary to expand the functionality, and a narrowly focused laser engraver for the house will not be able to perform more complex tasks. Nevertheless, there is a basic separation of such devices, depending on the nature of the processing of materials with different characteristics - these are gas models and solid-state ones.

That is, two varieties differ source,from which the laser beam is formed. Consequently, the quality of processing also changes. Gas models are cheaper and at the same time cover a wide range of materials - we can say that it is a universal device for working with leather, plastic, metal and other billets. In turn, solid-state devices are distinguished by special radiation properties, but the range of materials in this case is extremely small. It can be said that this is a narrow-beam laser engraver for metal, although it is used in some types of plastics. The main advantage of this device is the high precision of processing on metal surfaces.

Power selection

If you plan to work with small details, thenit is better to refer to models that have a power of up to 40 watts. Such devices are optimal for miniature processing of short-focus lens. For example, using this model, you can make a print with a detailed drawing of small characters. But if you need a laser engraver for stone, which provides the cutting function, then the power should be higher. At a minimum, one should be guided by instruments with a power potential of 60 W. Typically, such devices are equipped with mid-focus lenses of 2.5 inches.

It must be borne in mind that the power is chosen notOnly on the characteristics of the material being processed. The range of operations that are planned to be performed with its help, as well as the thickness of the surface, is important. In addition to the described power options, there are models of 20 W, and 120-watt versions. So, if you plan to process a metal sheet with a thickness of more than 1 cm, then a desktop laser engraver with a power reserve of 100 W is suitable. Conversely, for a delicate operation with pliable material, one should be guided by the lower limit of the force potential.

Additional Features

If the choice fell on a productive device, then inIt should also provide for a cooling system. This addition will provide a continuous workflow that is user-friendly, and safe for the instrument itself. The most technological versions are equipped with automatic focusing. This, again, is a desktop laser engraver that will allow you to perform large amounts of work with maintaining high quality. However, the cost of such devices is much higher than that of simple models. For home use, the most convenient and practical devices are usually chosen. Manufacturers take this into account, giving the internal filling of engravers the possibility of programming. That is, the user can only set the working program, and then the most complex pattern will be realized. Thus, you can transfer the image from the photo to the metal sheet.

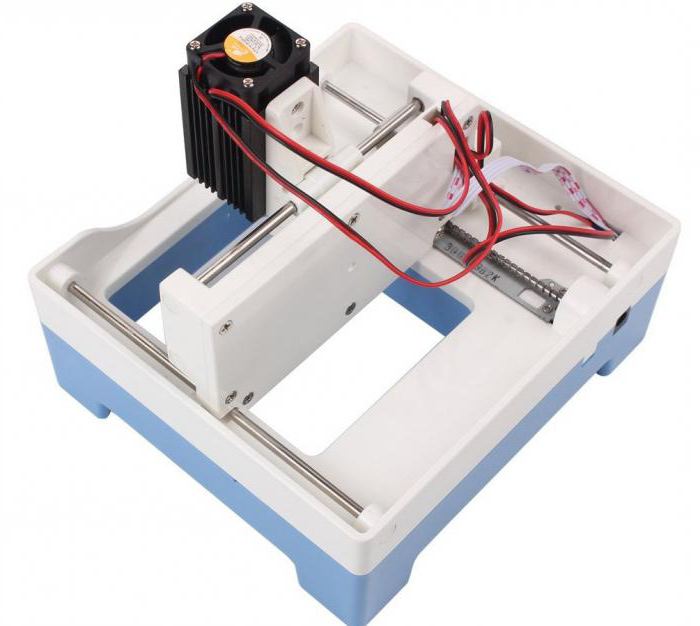

Laser mini-engraver - what's the feature?

These are portable models that differsmall size, but at the same time have a wide functionality. This class of engravers is quite common among amateurs, so manufacturers tend to give such models new ergonomic properties. For example, a laser mini-engraver can be used in conjunction with a laptop or computer. It is enough to connect the device through the USB port and prepare to transfer the digital image to the working surface. However, this is where one significant drawback lies. Due to understandable reasons, mini-devices have low power, so they are not suitable for working with solid materials. But the mini-engraver is convenient to use in the design of glass, wood, leather and plastic parts.

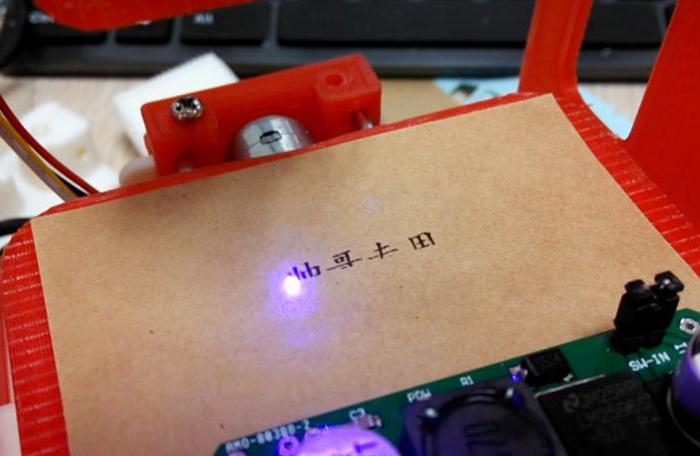

Reviews about model Neje

One of the most famous manufacturers of homemachines for engraving is the company Neje. The ruler of this manufacturer is regularly updated with interesting versions. In particular, the low-cost laser engraver of the JZ-5 series is praised for the quality of the assembly and the possibility of automatic positioning. The model works with different types of materials, including wood, plastic, glass and leather.

The peculiarities of the model include the highspeed processing, which is 10 times the capacity of competitors. Users are noted and high accuracy. This device is focused on miniature engraving - again, according to the owners, the device can perform a distinguishable inscription, even on a toothpick. If you need a laser engraver for plastic or wood, then this option can be optimal. It can be purchased for 10 thousand rubles, which is good for a technological and functional appliance.

Reviews about the engraver JDJG

A worthy option also offers Chinesemanufacturer JDJG. Already in the standard modification, the device allows performing both engraving and cutting. Among the materials that can be given to this device, solid wood and leather can be noted. True, the reviews note that this laser engraver for the house has more processing capabilities due to the power of 40 watts. Of course, a stone with a metal can not be engraved with it, but some types of plastics also succumb to it.

Reviews about Dragon Diamond

The manufacturer received many positivereviews from fans to the model LZ-M40A. Although the modification also has average power, it has strengths in the form of a cooling system, high speed and high-tech hardware stuffing. If you need an accurate and easy-to-use laser engraver for your home, then this option should be considered. The only drawback of this model is a high price - 30 thousand rubles.

Features of cutting different materials

The most popular material for engravingThe laser is considered to be wood. In many respects this is due to its soft structure. For example, wood panels with a thickness of 15 mm are well cut. But in the course of work, an air blowing system must be provided for the removal of combustion products. Optimum for such processing and plastic. Thermoplastics and facing panels are best suited, and with polycarbonate, with a small capacity of the machine, problems may arise. In this case, it is better to use a laser engraver for metal of solid-state type. As for the stone, it is provided that a suitable device is used, and it is easily processed. True, the quality of the cut may suffer due to incorrectly selected ligaments.

Conclusion

Household engravers are still considered specificequipment. Nevertheless, interest in laser models is steadily growing, due to the convenience of using such devices and a relatively affordable price - in any case, compared with professional machines. For example, a laser engraver for a stone today can be purchased for 30-40 thousand rubles. For comparison, specialized units are estimated at hundreds of thousands. Of course, the characteristics of the functionality, performance and quality of the picture in this case significantly increase, but for home use it does not matter. At the same time, the qualities of portable laser engravers are being improved at a rapid pace, as evidenced by their automation supply and the ability to specify cutting programs.

</ p>