Cutting mode for turning: elements and concept of cutting

One of the multifunctional processing methodsmetals is turning. With its help, roughing and finishing are carried out in the process of manufacturing or repairing parts. Optimization of the process and effective high-quality work is achieved by rational selection of cutting modes.

Process Features

Turning is carried out on specialmachine tools with the help of cutters. The main movements are performed by the spindle, which ensures the rotation of the object fixed to it. Feeding movements are performed by the tool, which is fixed in the support.

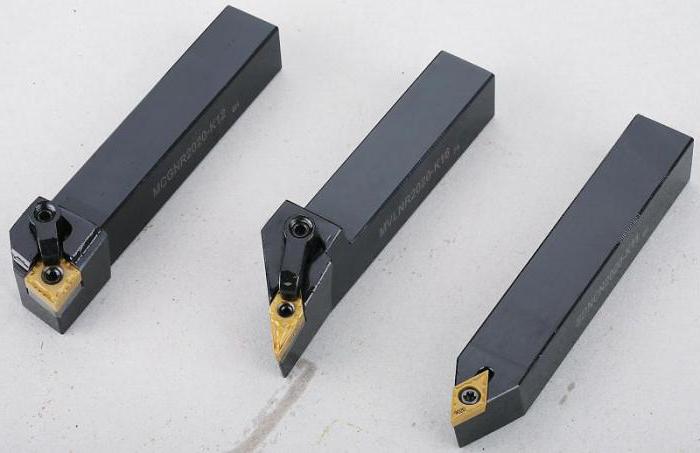

The main types of characteristic works are: end and shaped grinding, boring, processing grooves and grooves, cutting and cutting, threading. Each of them is accompanied by productive movements of the corresponding inventory: passing and stubborn, shaped, boring, pruned, cut-off and threaded cutters. A variety of types of machines can handle small and very large objects, internal and external surfaces, flat and bulk blanks.

The main elements of the modes

The cutting mode for turning isa set of parameters of the metal cutting machine, aimed at achieving optimal results. These include the following elements: depth, feedrate, frequency and spindle speed.

Depth is the thickness of the metal,for one pass (t, mm). Depends on the given indicators of purity and the corresponding roughness. For rough drafts t = 0.5-2 mm, for finishing - t = 0.1-0.5 mm.

Feedrate is the tool travel distance inlongitudinal, transverse or rectilinear direction relative to one revolution of the workpiece (S, mm / rev). Important parameters for its determination are the geometric and qualitative characteristics of the turning tool.

The spindle rotation frequency is the number of revolutions of the main axis to which the workpiece is mounted, which is performed over a period of time (n, r / s).

Speed is the width of the pass for one second with the correspondence of the given depth and quality provided by the frequency (v, m / s).

The power of turning is the indicator of the consumed power (P, H).

Frequency, speed and strength are the most importantinterlocking elements of the cutting regime during turning, which specify both the optimization parameters for finishing a particular object, and the rate of operation of the entire machine.

Initial data

From the point of view of the system approach, the turning processcan be considered as the smooth functioning of the elements of a complex system. These include: lathe, tool, workpiece, human factor. Thus, the list of factors influences the effectiveness of this system. Each of them is taken into account when it is necessary to calculate the cutting mode during turning:

- Parametric characteristics of the equipment, its power, the type of regulation of spindle rotation (stepped or stepless).

- Method of fixing the workpiece (using a faceplate, faceplate and a lunette, two lunettes).

- Physical and mechanical properties of the processed metal. It takes into account its thermal conductivity, hardness and strength, the type of chips produced and the nature of its behavior relative to the inventory.

- Geometrical and mechanical features of the tool: sizes of angles, holders, radius at the top, size, type and material of the cutting edge with appropriate thermal conductivity and heat capacity, impact strength, hardness, strength.

- Preset surface parameters, including its roughness and quality.

If all the characteristics of the system are taken into account and rationally calculated, it becomes possible to achieve maximum efficiency of its operation.

Criteria of turning efficiency

Turned partsfinishing, are often the components of responsible mechanisms. The requirements are met based on three main criteria. The most important is the maximum performance of each of them.

- Correspondence of the cutting tool materials and the grinded object.

- Optimization of supply, speed and depth between each other, maximum productivity and quality of finishing: minimal roughness, accuracy of molds, absence of defects.

- Minimal resource costs.

The procedure for calculating the cutting mode during turning is carried out with high accuracy. There are several different systems for this.

Methods of calculation

As already mentioned, the cutting regime for turningprocessing requires the consideration of a large number of different factors and parameters. In the process of technology development numerous scientists have developed several complexes aimed at calculating the optimal elements of cutting modes for different conditions:

- Mathematical. Implies an accurate calculation of existing empirical formulas.

- Graphoanalytical. Combining mathematical and graphical methods.

- Tabular. Selection of values corresponding to the specified working conditions in special complex tables.

- Machine. Use of the software.

The most suitable one is chosen by the executor depending on the tasks assigned and the mass production process.

Mathematical Method

Analyzes the cutting modes forturning. Formulas exist more and less complex. The choice of the system is determined by the features and the required accuracy of the results of the miscalculations and the technology itself.

Depth is calculated as the thickness difference of the workpiece before (D) and after (d) processing. For longitudinal work: t = (D - d): 2; and for transverse: t = D - d.

Permissible supply is determined in stages:

- figures that provide the required surface quality, Swool;

- feedrate taking into account the characteristics of the tool, SR;

- The value of the parameter, taking into account the features of securing the part, Schildren.

Each number is calculated from the correspondingformulas. As the actual feed, the smallest of the obtained S is selected. There is also a general formula that takes into account the geometry of the tool, the specified requirements for depth and quality of turning.

- S = (Cs* Ry* ru): (tx* φz2), mm / rev;

- where Cs - Parametric characteristics of the material;

- Ry - specified roughness, μm;

- ru - radius at the top of the turning tool, mm;

- tx - depth of turning, mm;

- φz - angle at the tip of the tool.

Speed parameters of spindle rotation are considered for different dependencies. One of the fundamental:

v = (Cv* Kv): (Tm* tx* Sy), m / min, where

- Cv - complex coefficient, generalizing the material of a part, tool, process conditions;

- Kv - an additional coefficient characterizing the features of turning;

- Tm - tool life, min;

- tx - Depth of cut, mm;

- Sy Feed rate, mm / rev.

Under simplified conditions and for the purpose of the availability of calculations, the speed of turning the workpiece can be determined:

V = (π * D * n): 1000, m / min, where

- n is the speed of the spindle of the machine, rpm.

Equipment used:

N = (P * v): (60 * 100), kW, where

- where P is the cutting force, H;

- v - speed, m / min.

The above procedure is very laborious. There is a wide variety of formulas of varying complexity. Most often it is difficult to choose the right ones in order to calculate the cutting modes for turning. An example of the most universal of them is given here.

Tabular method

The essence of this option is that the indicatorselements are in the normative tables according to the initial data. There is a list of directories in which the values of feeds are given depending on the parametric characteristics of the tool and the workpiece, the geometry of the tool, the specified surface quality indicators. There are separate standards that contain the maximum permissible limits for various materials. The starting factors necessary for calculating the speeds are also contained in special tables.

This technique is used singly orsimultaneously with the analytical one. It is convenient and precise in application for simple serial production of parts, in individual workshops and at home. It allows you to operate with digital values, using a minimum of effort and benchmarks.

Graphoanalytical and machine methods

The graphical method is an auxiliary andbased on mathematical calculations. The calculated results of the feeds are plotted on a graph, where the lines of the machine and tool are drawn and additional elements are determined on them. This method is a very complicated complex procedure, which is inconvenient for batch production.

The machine method is an accurate and affordable option forexperienced and novice turner, designed to calculate the cutting modes for turning. The program provides the most accurate values in accordance with the given initial data. They must include:

- Coefficients that characterize the material of the workpiece.

- Indicators that correspond to the features of the instrumental metal.

- Geometric parameters of turning tools.

- Numerical description of the machine and methods of fixing the workpiece on it.

- Parametric properties of the object being processed.

Difficulties can arise at the stage of numericalthe description of the initial data. Correctly setting them, you can quickly get a comprehensive and accurate calculation of cutting modes for turning. The program may contain inaccuracies in the work, but they are less significant than in the manual mathematical version.

Cutting mode for turning - an importantthe design characteristic that determines its results. Simultaneously with the elements, tools and cooling-lubricating substances are selected. A full rational selection of this complex is an indicator of a specialist's expertise or his perseverance.

</ p>