Electromagnetic motors: circuit, principle of operation

Electromagnetic motors are devices,which work by the principle of induction. Some people call them electromechanical converters. A side effect of these devices is the abundant release of heat. There are models of constant and variable type.

Also, the devices are distinguished by the rotor type. In particular, there are short-circuit and phase modifications. The scope of electromagnetic motors is very wide. You can meet them in household appliances, as well as industrial units. They are also actively used in aircraft construction.

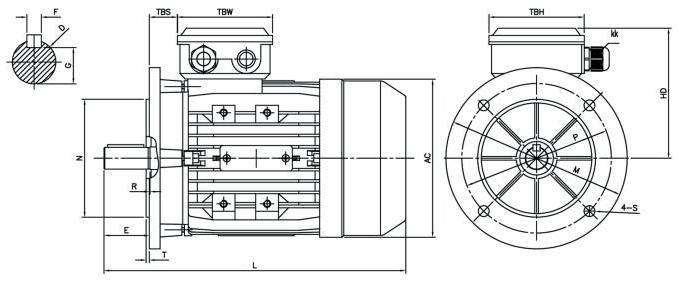

Motor circuit

The circuit of the electromagnetic motor includesstator, and also the rotor. Collectors, as a rule, are of the brush type. The rotor consists of a shaft, as well as a tip. To cool the system, fans are often installed. Roller bearings are available for free rotation of the shaft. Also, there are modifications with magnetic cores, which are an integral part of the stator. A contact ring is located above the rotor. In powerful modifications, a retracting relay is used. The current is fed directly through the cable.

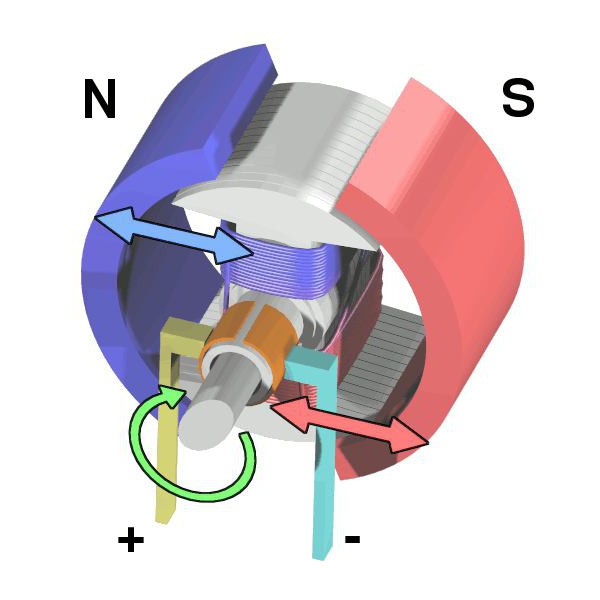

The principle of the engine

As stated earlier, the principle of operation is constructedon electromagnetic induction. When the model is connected, a magnetic field is formed. Then the voltage on the winding increases. The rotor is activated by the force of the magnetic field. The frequency of rotation of the device primarily depends on the number of magnetic poles. The collector in this case plays the role of a stabilizer. The current is fed into the circuit through the stator. It is also important to note that shrouds and seals are used to protect the engine.

How to make your own hands?

Make a conventional electromagnetic motor with your ownhands quite simply. The first thing to do is to work on the rotor. To do this, you need to find a metal rod, which will play the role of a shaft. It also requires two powerful magnets. The stator must have a winding. Then you just have to install the brush collector. Electromagnetic self-made motors are connected to the network through a conductor.

Modifications for machines

Electromagnetic Engines for Automobilesare made only of a collector type. Their average power is 40 kW. In turn, the nominal current parameter is 30 A. Stators in this case are used bipolar. Some modifications have a terminal box. Fans are used to cool the system.

Also in the devices are provided specialholes for air circulation. Rotors in engines are installed with metal cores. Seals are used to protect the shaft. The stator in this case is in the casing. Electromagnetic motors for machines with retracting relays are rare. On average, the diameter of the shaft does not exceed 3.5 cm.

Devices for aircraft

The work of engines of this type is based onprinciple of electromagnetic induction. For this, the stators are of the three-pole type. Also, electromagnetic aircraft engines include brushless collectors. The terminal boxes in the devices are located above the contact rings. An integral part of the stator is the anchor. The shaft rotates by means of roller bearings. Some modifications use brush holders. It is also important to mention the different types of terminal boxes. In this case, much depends on the power of modification. Electromagnetic motors for airplanes for cooling are equipped with fans.

Engines-generators

Electromagnetic motors-generators are producedwith special bendics. The circuit of the device also includes retracting relays. Cores are used to start the rotor. Stators in devices are of the bipolar type. The shaft is attached directly to them by roller bearings. Most engines have a rubber stopper. Thus, the rotor wears out slowly. Still there are modifications with brush holders.

Models with squirrel cage rotor

Electromagnetic motor with squirrel cageThe rotor is often installed in household appliances. The average power of models is 4 kW. Direct stators are used in a bipolar type. The rotors are attached to the rear of the engine. The shaft of the models is of small diameter. To date, most often issued asynchronous modifications.

Terminal boxes in the devices are absent. Special pole pieces are used to supply the current. Also, the motor circuit includes magnetic circuits. They are attached to the stators. It is also important to note that devices with and without brush holders are available. If we consider the first option, then in this case, special gears are installed. Thus, the stator is shielded from the magnetic field. Devices without a brush holder have a seal. Bendixs in the engines are installed behind the stator. Keys are used to fix them. The disadvantage of these devices is fast core wear. It arises because of the high temperature in the engine.

Modifications with phase rotor

Electromagnetic motor with phase rotoris installed on machines and is often used in heavy industry. Magnetic cores in this case are available with anchors. A distinctive feature of the devices is considered to be large shafts. Directly, the voltage to the winding is fed through the stator. A brush holder is used to rotate the shaft. Some of them have contact rings. It is also important to note that the power of the models averages 45 kW. The motors can be powered directly only from the AC mains.

Collector Electromagnetic Engine: The Principle of Operation

Collector modifications are actively used forelectric drives. The principle of operation is rather simple. After the voltage is applied to the circuit, the rotor is activated. The electromagnetic field starts the induction process. The excitation of the winding causes the rotor shaft to rotate. This drives the drive of the device. Bearings are used to reduce the frictional force. It is also important to note that brush holders are installed in the models. In the back of the devices there is often a fan. To ensure that the shaft does not rub against the seal, a protective ring is used.

Brushless Modifications

Collectorless modifications in our time are notare common. They are used for ventilation systems. A distinctive feature of these is the noiselessness. However, it should be borne in mind that the models are produced with low power. On average, this parameter does not exceed 12 kW. Stators in them are often installed in a bipolar type. The shafts are short. Special sealants are used to protect the rotor. Sometimes the engines are enclosed in a casing that has ventilation ducts.

Models with independent excitation

Modifications of this type differ in terminalmagnetic cores. In this case, the devices operate on the network only with alternating current. Directly the voltage is first applied to the stator. Rotors for models are made with collectors. At some updatings capacity reaches 55 kw.

By the type of anchors devices differ. Brush holders are often installed on the retaining ring. It is also important to note that collectors in devices are used with seals. Disks in this case are located behind the stators. Many engines have no bendixics.

Motor circuit with self-excitation

Electromagnetic motors of this type are capable ofboast of high power. In this case, the windings are of high voltage type. The voltage is supplied through the terminal contacts. Directly the rotor is attached to the brush holder. The operating current level in the devices is 30 A. In some modifications, anchors with brush holders are used.

Also there are devices with single-pole stators. The shaft is directly in the center of the motor. If we consider high-power devices, then they use a fan to cool the system. Also on the casing are small holes.

Parallel Excitation Models

Electromagnetic motors of this typeare made on the basis of brush collectors. Anchors are absent in this case. The shaft in the devices is fixed to the roller bearings. Also, to reduce the frictional force, special paws are used. Some configurations have magnetic cores. Connect models can only to a network with direct current.

It is also important to note that the marketthree-stroke modifications are presented. The brush holders in the devices are in the form of cylinders. The power models differ. On average, the operating current parameter at idling does not exceed 50 A. To enhance the electromagnetic field, rotors with a high-voltage winding are used. Some configurations use tips on magnetic circuits.

Devices of consecutive excitation

The principle of operation of this type of engines is quiteplain. The voltage is directly applied to the stator. Then the current passes through the winding of the rotor. At this stage, the primary winding is excited. As a consequence, the rotor is activated. However, it should be borne in mind that the motors are only able to operate on AC networks. The tips in this case are applied to the magnetic core.

Some devices are equipped with brush holders. The power of models ranges from 20 to 60 kW. Locking rings are used to fix the shaft. Bendixs in this case are located in the lower part of the structure. No terminal blocks. It is also important to note that the shaft is installed in various diameters.

Motors of mixed excitation

Electromagnetic motors of this type canused only for drives. The rotor here is most often installed with a primary winding. In this case, the power rating does not exceed 40 kW. The nominal overload of the system is about 30 A. The stator in devices is of the three-pole type. It is possible to connect the specified motor only to a network with alternating current. The terminal boxes at them are used with contacts.

Some modifications are equipped with brush holders. Also on the market are devices with fans. The seals are most often located above the stators. Devices operate on the principle of electromagnetic induction. Primary excitation is carried out on the stator magnetic circuit. It is also important to note that the devices use a high-voltage winding. Protective rings are used to fix the shaft.

AC Devices

A diagram of this type of model includes a statorbipolar type. The average power of the device is 40 kW. The rotor is used here with the primary winding. Also there are modifications that have bendixics. They are installed at the stator and play the role of an electromagnetic field stabilizer.

For driving the shaft, the driving gear is used. In this case, the feet are set to reduce the frictional force. Polespins are also used. Covers are used to protect the mechanism. Magnetic cores for models are installed only with anchors. On average, the operating current in the system is maintained at 45 A.

Synchronous devices

The synchronous motor circuit includesa double-pole stator, and a brush manifold. Some devices use a magnetic circuit. If we consider household modifications, then they use brush holders. On average, the power parameter is 30 kW. Devices with fans are rare. Some models use gears.

For cooling the engine on the housing there areventilation holes. In this case, the locking ring is installed at the base of the shaft. The winding is of low voltage type. The principle of synchronous modification is based on the induction of the electromagnetic field. For this purpose, magnets of different power are installed in the stator. When the winding is excited, the shaft starts to rotate. However, his frequency is low. Powerful models have collectors with relays.

Scheme of an asynchronous motor

Asynchronous models are compact and oftenare used in household appliances. However, in heavy industry they are also in demand. First of all, it should be noted their security. Rotors in devices are applied only to a single-pole type. However, the stators are installed with magnetic cores. In this case, the winding is of the high-voltage type. To stabilize the electromagnetic field there is a bandix.

It is fixed in the device thanks to a key. The retractor relay is located behind them. The shaft of the device rotates on special roller bearings. It is also important to note that there are modifications with brushless collectors. They are used mainly for drives of various capacities. The cores in this case are elongated, and they are located behind the magnetic cores.

</ p>