The engine "ZMZ-406 Turbo": description, characteristics and reviews

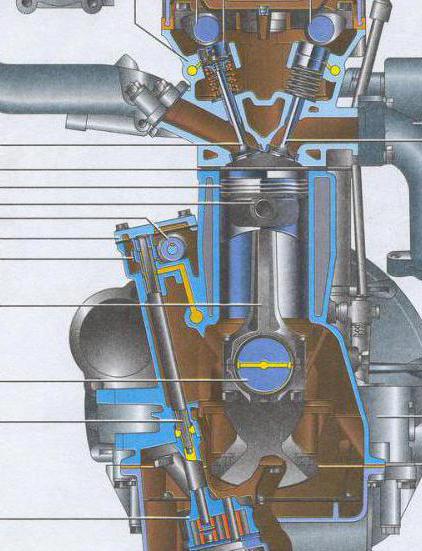

The domestic engine "ZMZ-406 Turbo" isreceiver of the classic analog, known as the index 402. The new engine somewhat resembles the Swedish "Saab", the body of the unit is made of cast iron, the camshafts have an upper location. The power plant includes 16 valves, hydraulic expansion joints. This design allows you to get rid of the owner of frequent valve adjustments. The timing gear is equipped with a chain, the nominal service life of which is not less than 100 thousand kilometers. Despite the simplicity of the design, the installation in question is much "advanced" than its predecessor. We will study the features of the device and the feedback of users about it.

"ZMZ-406 Turbo": characteristics

Below are the parameters of the considered motor:

- The years of production are 1997-2008.

- Feeding part - injector / carburetor.

- The arrangement of the cylinders is of the in-line type.

- The number of cylinders and valves on each element is 4/4.

- Piston movement - 86 mm.

- Compression - 9.3.

- The volume of the engine is 2286 cu. cm.

- The power index is 145 horsepower at 5200 rpm.

- The ecological standard is Euro-3.

- Weight - 187 kg.

- The fuel consumption in the mixed mode is 13.5 liters per 100 km.

- The nominal operating life of the unit is 150,000 kilometers.

- Installation - "Volga" 3102/31029/3110, (Gazelle, Sable).

Modifications

Several models of the ZMZ-406 Turbo engine were commissioned:

- Carburettor modification 406. 1. 10. Used on "Gazelle", consumes gasoline AI-76.

- Version 406. 2. 10. Injector motor, installed on the "Gazelle" and "Volga".

- Model 406. 3. 10. Applied to the "Gazelle" (AI-92).

Basic Faults

The engine "ZMZ-406 Turbo" is most often subject to the following faults:

- Hydraulic timing chain tensionerscan be jammed. In this regard, there is extraneous noise, no oscillation, further deformation of the shoe, until the entire chain is destroyed. In this regard, the advantage of the engine in question is that it does not bend the valve.

- Overheating of the power plant. A similar problem is also not uncommon. As a rule, such a breakdown occurs due to a clogged radiator or failure of a thermostat. Initially, it is recommended to check the coolant level and the presence of air plugs in the system.

- Increased oil consumption. Most often, the engine "ZMZ-406 Turbo KIT" is experiencing this problem due to the wear of oil seals and oil lifters on the valves. Also, the malfunction sometimes occurs because a gap is formed between the plate and the valve cover, through which oil leakage occurs. To fix the problem, just remove the lid and apply a sealant to the surface.

Other problems

Among other, frequently occurring malfunctions of the ZMZ-406 Turbo engine, the following can be noted:

- Often there are thrust failures due to the failure of the ignition coils. After replacing these elements, the operation of the motor is restored instantly.

- Knocking in the power unit. This problem occurs due to the wear of the hydraulic expansion joints. According to the manufacturer, the life of these parts is not less than 50 thousand kilometers.

- Deterioration of piston fingers, pistons and шатунных loose leaves that also leads to occurrence of extraneous sounds in the motor.

- The power unit is trod. In this case, you should check the candles, coils and compression.

- There is a fading of the power unit. Most often, "ZMZ-406 Turbo" stalls due to a broken wire, a crankshaft sensor or RXH.

In addition, there have been repeated failures inthe work of the clutch "ZMZ-406 Turbo" and a gasoline pump. In general, the causes of the malfunctions are typical for all domestic engines, including poor build quality. Nevertheless, the 406th model is much more efficient and practical than its predecessor, number 402. For reference: on the basis of the 406th ZMZ, the engines of the 405 and 409 series were developed, with a volume of 2.7 liters.

Forcing

One of the options for increasing the capacity of the unitis an atmospheric method with the installation of additional shafts. At the inlet, a cold air intake is installed, a receiver with an enlarged diameter. Then, the cylinder head is sawed, the combustion compartments are improved, the size of the channels is increased. At the next stage of the improvement of the ZMZ-406 Turbo motor, lightweight T-valves, 21083 series springs and new shafts, for example from OKB 38/38, are installed.

Use the standard tractor pistongroup does not make sense. They buy new forged-type pistons, a lightweight crankshaft. The node is balanced. A direct-flow exhaust is installed on a pipe with a diameter of 63 mm. As a result, the power will be about 200 horsepower, and the characteristics of the power plant will have a pronounced sports configuration.

"ZMZ-406 Turbo": tuning

The second way to improve theengine is to install the pressurization. In order for the device to transfer a high pressure normally, a reinforced piston block must be installed. The rest of the design is identical to the transformations carried out during atmospheric modernization.

Mounted turbine type Garrett 28 sappropriate collector, piping, intercooler, nozzles 630 cc, exhaust system at 76 mm, DBP + DTV. The output power as a result will be no less than 300 "horses". If desired, you can change the injectors to a 800 cps configuration, which will further increase the engine's power, but such a system will lead to rapid deterioration of the unit. It will be necessary to install a new compressor, for example the Eaton M90. Then you need to fine-tune it. As practice shows, this modernization allows you to get a motor without failures, the thrust of which is felt from the bottom.

Inlet system configuration

This operation using a new timing kit"ZMZ-406 Euro-2 Turbo" is one of the most important moments that affect the parameters of the power plant. In the system under consideration, wave processes occur which are tuned to a specific range of revolutions. In the standard version, the node has ambiguous characteristics.

To the pluses can be attributed a short intake path,designed for high turnover. On the other hand, the inlet openings on the filter have a rather small cross section. The filter element itself is characterized by high efficiency and does not require replacement with a zero version, which is difficult to maintain and does not have a high efficiency.

To improve performance and fillcylinders at high speed, experts recommend removing the standard body of the atmospheric filter. The solution to this problem is manifested in the installation of the "cold inlet" system. At the place of installation of the air filter element, a closed volume is equipped so that the air flow comes exclusively from the outside. An additional partition will help in this.

As an option, you can do nothing under the hoodSeparate, and withdraw the air intake under the bumper. However, in this case, there is a danger of getting a hydraulic shock, while there is a slight decrease in engine power.

Finalization of cylinder head

This operation is reduced to polishing channels,Smoothing of all sharp residues in the combustion chamber and at the bottom of the piston. For the motors under consideration it is recommended to install the cylinder head gasket from the unit 405.22 (Euro-3). It is made of solid metal, is more reliable and thin. As a result, it allows to increase the compression and economy of the engine.

The next stage is the installationcamshafts with increased valve travel. For regular operation of the power plant in city conditions, experts advise using a pair of shafts such as 30/34.

Other ways to modernize

The motor can also be improved byinstallation of the set of timing "ZMZ-406 Euro2 Turbo". In addition, the crankshaft is mounted with an increased stroke of the crank assembly. This will give an opportunity to increase the working volume to 2.5 liters. In addition, the new crankshaft uses pistons with a 4-millimeter-long finger. He should not leave the plane of the block and hit the cylinder head.

A good option for powertrainsThe considered model is the use of pistons with thin rings. They will reduce the dynamic loss, which is especially important for turntable engines. Alternatively, it is possible to ease the piston and connecting rod groups, but this will not have a special effect on motors with a speed of up to 7,000 rotations per minute. Reducing the mass of the flywheel on such samples leads to intermittent operation, a rapid set of turns and the same intensive dropping. This is not very convenient, especially when moving around in the city.

Reviews

As evidenced by user feedback, the motor"ZMZ-406" is much better than its predecessor in terms of capacity and operation. However, he is not without flaws. In this regard, many owners are tuning the unit. How to do this was discussed above. The main thing is not to overdo it with modifications, as excessive introductions increase the characteristics of the installation, but also lead to rapid wear. Here you need to competently compare the resulting effect and the estimated work resource. It is worth noting that after the modification of any motor, subsequent adjustment of its control system is required. Help in adjusting a specific engine will help the program Molt, which optimizes the performance of each engine, depending on its features.

</ p>