Homemade shotgun. Drawing of the gun. How to make a gun

Homemade shotgun for hunting underwater canmade of various materials. At the same time, the weapons of harpoon and traumatic action are distinguished. The lethal force depends on the principle of operation and the components used in the design. Consider the features of the most popular modifications.

Homemade air rifle

Such a model can be assembled if availablethere are parts from an automatic analog. First, the stem part is removed, then attached to the bottom of the cage at a distance of about 40 millimeters. Mounted sheptalo and compensators. Depending on the design of the fuse, the last elements can not be installed. The ramrod is attached to the base of the clip. Place the safety lock on the line side. It is worth noting that the feeder must not touch the safety ring during operation.

Model with a pair of springs

Homemade shotgun of this modification hasrather complex construction. You should use a wide clip and choose a suitable pipe. Then the sear is mounted on it. It is desirable to make a winding along the edge of the barrel.

The fighting spring mechanism is fixed tocentral axis, but without contact with the line. After mounting the springs proceed to install the feeder. The slide should be placed next to the clip. Alternatively, a winding can be used for this purpose. In addition, you can install the pads and the locking latch.

How to make a gun with a solid line?

Such models are among the mostcommon variations. The feature includes the possibility of using all clips and compact dimensions. At the same time, a wide whisper to such rifles does not fit. Assembly begins with the barrel, the screws are attached to the front and rear. Then the holder is mounted.

If the homemade shotgun is supposedto install a clip made by own hands, it is necessary to calculate the length of the sear. The edges of the knot should be carefully sharpened and cleaned using a file or emery stone. Then the line and fuse are installed. At the final stage, the descender and the ramrod are mounted. After the installation of the compensator, fix the fighting spring.

Modification with direct feeder

To make a homemade rifleit is necessary to choose a pipe of suitable length and diameter. The minimum thickness of the element is 100 mm. Next, cut the working channel, the depth of which should be at least 6 mm. If desired, the overlay is mounted, the cage is fixed after the installation of the sear.

If necessary, a fuse(optional), a dense winding is performed, which allows you to reduce the impact of the shot. The axis is desirable to choose steel, and the sear can be made of aluminum alloy. Compensators to this model fit almost any. The feeder as a result is carefully sharpened in such a way that he does not touch the slide.

Variant with a pair of skid

Such homemade guns are used forhunting. As in the case with most analogs, you will need to select a suitable pipe to start the production. Its length should be at least 120 millimeters, and the thickness - 44 mm. After grinding, the channel is cut. Its width should not exceed 50 mm. This jack is designed for placing the ramrod. Then a slide with a wide piston is installed.

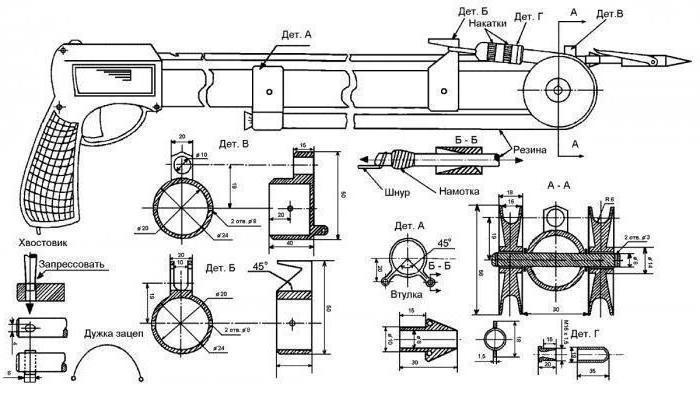

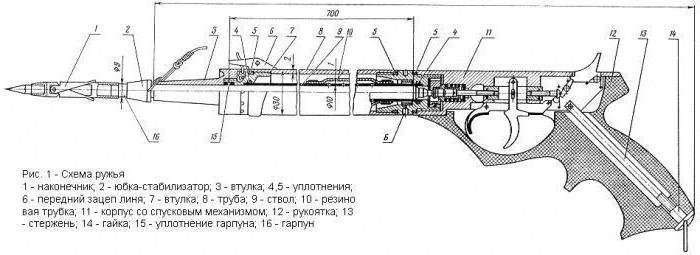

To fix the pipe, you can apply a hook, andthe clip must be made of wood. If desired, add a metal patch. After the installation of the sheptal, a working spring is connected, the diameter of which must be at least 35 millimeters. At the last stage, the line and the trigger are mounted. Winding in this version, as a rule, is not used. The drawing of the gun is shown below.

Hawaiian model

This modification is designed for underwaterhunting, is equipped with metal pads and has a simple design. After preparing a suitable pipe length of 120 mm it is grinded on a special machine. Then the speakers are mounted from the front part at a distance of 20 mm, and at the rear - by 40 mm. Such a system will provide an opportunity to reliably fix the barrel on the cage.

It will be required to cut a channel at the edge of the pipe,The whisper is mounted after the lining. Further winding is carried out, which will allow to fix the tench. At the end, a ramrod and trigger are installed. Compensators in this design are not provided.

Shotgun on compensator

Such a mechanism is rather complicated. But if there are parts from a traumatic gun, then the task is simplified. First, choose a large shoe width of at least 6.5 millimeters. It makes a channel 2-2,5 mm. It is desirable to fix the searche on the winding made of aluminum. At the end of the barrel a hook is attached, and after mounting the cage a fuse is mounted. The ramrod is of a hollow type, the width of the cage is not less than 45 mm.

The considered self-made underwater gunequipped with a long line. The compensator is attached to its base. The feeder is placed near the cage. When making the device, make sure that the compensator does not come in contact with the trigger unit. The distance to the latch should be about 20 millimeters, which will avoid overlapping the compensator when it is turned on.

Design with aluminum winding

Such a modification is popular inlargely due to the provision of a good seal. The assembly of the device begins as standard from the barrel. The clip can be taken with a small width. This will make it possible to fix the winding more tightly. Optimal option in choosing a sear is a version with three prongs. The fuse is individually selected.

An important role in this constructionlength of the line. The compensator is mounted at the final assembly stage. The trigger assembly can not be manufactured independently, so it would be reasonable to use a similar element from an air gun.

Continuous winding

How to make a gun with a continuous winding,consider further. This requires a pipe with a wide clip, whispered with three prongs. The frame must coincide with the line in width, when installing it, care must be taken. After installing this unit, the winding process is started. It should be noted that it should not be superimposed on the ramrod.

Then the compensator is installed andfeeding mechanism with a working spring. It is recommended to use L-shaped latches. In the final it will remain to fix the trigger assembly, which can be taken from any rifle.

Version with overlays

Such a model of a homemade shotgun for hunting underwater is one of the most popular modifications. Among similar equipment, it has the best indicator of tightness. Begin the assembly traditionally from the trunk. The clip is fixed after mounting the sear. The lining itself is fixed with a special glue. The minimum thickness of this element is 2.2 millimeters. When using a long ramrod, the lining extends up to the cage. Then the latch on the barrel is fixed.

The result

In conclusion, we can say thata self-made rifle for underwater hunting is not difficult. In this case, the user can choose a design that is optimally suited for materials, cost and design. These recommendations will allow creating a reliable weapon for hunting even for novice consumers, and the drawings contain detailed visual information on the number and name of parts.

</ p>