Staircase from a log with your own hands

A log ladder has many advantages over products made from other materials. Wood is environmentally safe, strong enough and durable. This design is suitable for any interior.

But most often it is chosen for premises,which are decorated in country style. If you yourself make such a ladder, you can save, and also make the room more comfortable. Before installing the structure, it is necessary to process the wood so that it can last even longer.

Preparation of tools

Before you make a ladder from a log, you need to prepare all the tools and materials, among them:

- saw;

- Grinder;

- joiner's tools.

It is better to choose an electric or chainsaw, which will not only facilitate, but will speed up the process. As for the grinding machine, it will allow to process the wood, otherwise there can not be a splinter in any way.

Recommendations for the manufacture of wooden stairs

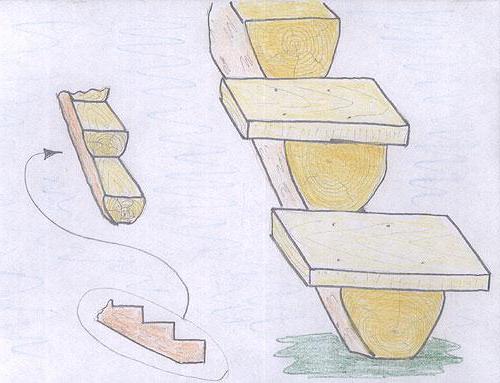

A log ladder must be made ofhalf-timber, which will be able to give the design a solidity and solidity. In this case, you can use the product for several decades, and in the process the material will not lose its appearance. If the steps are made of half-brushes, you will need a kosour or a powerful bowstring. In this case, the product can be located not only inside, but also outside the room.

Before the beginning of work it is necessary to determine the slope,the size of the future staircase and the number of steps. It is important to choose fasteners and support elements. To determine the length, it is necessary to calculate the height between the ceiling and the ground floor of the first floor. The optimal solution will be a sloping and wide staircase, because a steep construction can be dangerous.

The width of the steps should be selected,so that a person could conveniently put one foot on one of them. The average value lies in the range from 25 to 30 cm. If the width is too large, the person will stray from the step, climbing upward.

Material selection

Before you make a ladder oflogs, it is important to choose the material. Do not buy wood with a high moisture content, because in the course of time mold and fungus will appear. But after drying such logs in their base, cracks may appear, as a result the product is deformed and will lose its original form.

Sometimes for construction use logs fromdismantled logs, but it is important to remove nails and old fasteners from them beforehand. In the presence of blue and mold on the wood, it is necessary to treat the surface with chemical whitening compounds. At the next stage, the material is ground, cleaned from deformations and knots. Antiseptic solutions can be used for protection. The ends of the material are covered with resin, the processing must also be subjected to those logs that are installed on the ground.

If the staircase from the log is outside,then its surface should be completely covered with resin. And after installation, the structure is opened with paint or varnish, which will protect the material from moisture. If the ladder is to be subjected to high operational loads, then it is better to choose hardwoods like beech or oak for work.

For external staircases, coniferousrocks, because they contain more resin, which can protect the material from moisture. In addition, this substance produces an antiseptic effect. A ladder made of logs, the photo of which is presented in the article, can be made from inexpensive larch, but for steps it can go half-way.

Assembling

At the first stage of installation, it is necessary to fix the bearing elements, which can be a kosour or bowstring. After that, you can begin to cut the groove on the base for laying the logs.

The stage is fixed by self-tapping screws orspecial hexagon head screws. Their thickness can be equal to 8 or 10 mm. Preliminary prepared grooves, after these places are decorated with wooden stoppers.

Methods of work

As the most appropriate value of the angleThe slope of the bowstones protrudes from 25 to 35 °. Determining the width of the ladder, it is necessary to take into account that on it two persons must pass freely. The width of the tread should be determined in relation to the average size of the foot, it is also important to determine the height of the risers, the last of which will be a limit of 15 to 20 cm. The most convenient value of the railing height is 90 cm. The distance between the balusters should be 12 cm.

For the production of steps, logs are used,which are sawed and supplied with special grooves for fastening. Kosouur should be located in the place where the staircase will be. At the point of its attachment, it is necessary to make through holes, covering the cup areas with adhesive composition. When a ladder is made from logs with your own hands, the fixing of steps is carried out not only with glue, but also with anchors, and also with washers for each step. The upper part of the kosoura on the floor does not fasten, because when the wood is used it will shrink. The handrail is fixed on the screws, and the hats can be hidden under the stoppers made of wood. Once the glue dries, the design can be varnished.

Conclusion

A staircase to a house from a log should not only bestrong and durable, but also convenient for operation. Therefore, one of the important values is the width of the span. The smaller it is, the less man will have freedom of action. The minimum value is 0,9 m, in this case it will be possible to get a single staircase.

Width is not recommended to do less, becauseThis parameter is dictated not only by the convenience of operation, but also by the comfort of moving furniture and other large-sized elements. If the house has enough free space, you can increase this value to 1.5 m. The width of the span is limited only to the decreasing direction, but if you want to exceed the recommended limits by more than 10%, then additional amplifications should be used.

</ p>