Laser cutting of plywood - the basis and fineness

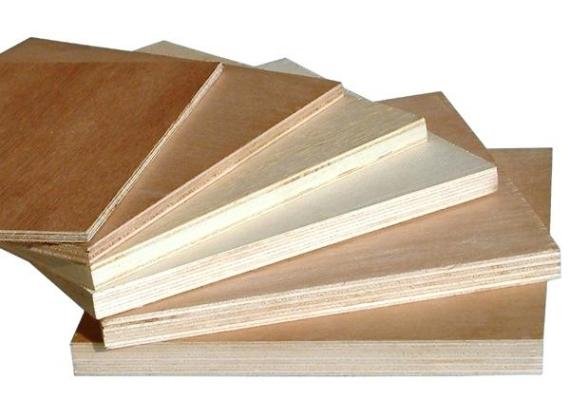

Each of us knows what he is likeplywood. Being a laminated material consisting of sheets of peeled veneer, firmly glued together, plywood is characterized by strength and stability of form. Therefore, it is widely used in the production of furniture and various interior decoration items.

In order to give the plywood sheet the desired shape,and in some cases it is design patterns or ornament, laser cutting of plywood is made. Being the newest modern way of cutting sheet and lamellar materials, laser cutting allows to realize and execute from plywood the most complex design and design ideas.

It should be noted that laser cutting of plywood is notsuch a simple matter, as it seems at first glance. The composite structure of the material, the heterogeneity of the thicknesses of veneer and resin layers, the multidirectional nature of the fibers and air bubbles all require certain skills.

For a long time, laser equipment wasquite expensive, so craftsmen were forced to invent their own devices for these purposes. As a result, on such devices many amators produce rather high-quality laser cutting of plywood with their own hands.

Principle of cutting plywood by laser

For performance of works on cutting of plywood is necessarymanual or electric machine. Laser cutting of plywood is caused by a point impact of the beam on the surface, i.e. it is carried out in a non-contact way and excludes the occurrence of waste in this case.

Homemade laser

You can design a laser for cutting plywoodindependently with the help of a matchbox with DWD-drive. Such a device provides a sharp burst of temperature at the point of contact of the beam with the surface being treated, which leads to the burning of wood with a thickness of 0.01-0.02 mm. This treatment of plywood is important for engraving and cutting small items. But it has its own peculiarity - it leaves dark edges in the place of cutting.

Cutting plywood with your own hands

Laser cutting of plywood with your own hands is performed withusing a tube with gas (nitrogen + helium + carbon monoxide), power from 20 watts of the main source generating radiation. An electric discharge is applied to it, which causes the appearance of monochromatic radiation directed to the surface being treated by means of a mirror system. Also, take care of the correct elements for the transformation of power.

For comfortable and correct operation, the handset should beequipped with a powerful cooling system. This is necessary, because during its operation the shell becomes very hot. To prevent overheating, the tube "clothes" in the second shell, through which the coolant circulates continuously during operation.

Such a cooling system can be done with the help ofCapacity for a liquid volume of 80-100 liters and a water pump. As a cooling liquid, freon is most often used. Also, you should take care of a quality transformer for good radiation and extraction to divert the combustion products.

Professional cutting of plywood with laser

But of course, self-made designs forlaser processing of plywood is not suitable for performing one or several small jobs. In this case it is much easier to contact a company in which professional laser cutting of plywood is performed. The price of this work is determined by the thickness of the material, the length of the cut and is practically independent of the complexity and shape of the treatment.

It is necessary to take into account the fact that laser cuttingplywood is best suited to the material of the brand FC. In it, the layers of plywood are glued together with carbamide resin. The fact is that it is less heat-resistant than phenolic or bakelite varnish and, accordingly, is better liable to laser treatment. Those. It takes much less of the cost of the laser beam to break its polymeric bond and the disintegration of the molecule. And this, in turn, significantly improves the cutting performance.

Therefore, if you need to cut plywoodlaser, and you are not an expert in this field, consult with professionals about the material and picture of cutting. Undoubtedly, having done everything according to their recommendations, you will surely receive a product that will attract attention and please the eye with the irreproachability of its form.

</ p>