I-beam: dimensions. I-beam wooden beam

Beams are used in construction during assemblyroofs, floors, floors, etc. There are a variety of types. The most durable type is the I-beam - a special design, repeating the letter "H" in section. This building material can be made of metal or wood.

Metal I-beam

When this type of rolled metal is produceduse both carbon and low-alloy steel. I-beams are used in many spheres of civil and industrial construction. Usually, this material is used in case it is necessary to impart increased strength and rigidity to the frame of the structure or to some of its parts. There are I-beam welded and hot-rolled steel beams. The latter are most popular.

By the strength of this material there is one moreadvantage. I-beam joists are very resistant to temperature fluctuations. Therefore, they are often used also in the construction of unheated rooms.

Scope of application

Basically I-beam, the size of whichcan be different, it is used in construction when building ceilings of industrial and civil buildings. Also, this type of rolled metal is often used for assembling bridges and for reinforcing mines. Very wide use of this material found in car building and automotive industry.

Types of I-beams

This type of rolled metal is classified not only inmethod of manufacture, but also by design features. The I-beam can have both parallel shelves and angled ones. In the latter case, the rolling is divided into:

- special,

- normal (with a slope of shelves from 6 to 12%).

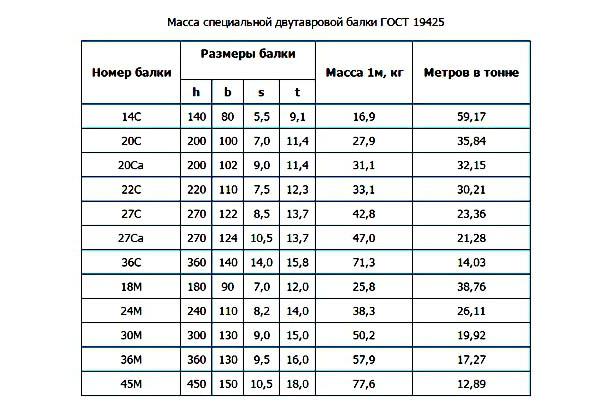

Special I-Beams (GOST 19425-74), in turn, are classified into:

- Designed for reinforcement of shafts (marked with the letter "C");

- Used in the manufacture of suspension ways (the letter "M").

Beams with parallel shelves (GOST 26020-83) are divided into:

- normal (marked "B"),

- broadband (W),

- Column (K).

Also, the metal I-beams may differ in the thickness of the shelves and the wall.

I-beam: dimensions

The height in the cross-section of this type of rolled metal can also behave different. This indicator is regulated by GOSTs, and it can be determined by the number of the beam. Thus, a material 140 mm high will be marked as 14C, 360 mm - 36M, etc.

The concrete dimensions of the structural elements of this type of rolled metal are determined by special tables. Of these, one can know the weight of the I-beam.

Legend:

- b - shelf width,

- t is its average thickness,

- S is the wall thickness,

- h is the height of the I-beam,

- R is the radius of the inner curvature,

- R- radius of the curvature of the shelf.

Beams I-beams wooden

This kind of building material, likemetal, characterized by increased strength and excellent performance characteristics. The bridge of the I-beam is usually made of plywood or OSB, the shelves are made of planed sawn timber. There is also a glued variety. In this case, multilayer veneer acts as the edges. Glued I-beams are less prone to rot. In addition, they are more fire resistant.

I-beams are connected to each other fromwood with special brackets. The latter consist of parallel metal plates and a fixing device. Fasteners can have different sizes. If necessary, it will not be difficult to get an option ideally suited to the height of this particular beam.

Scope of use

Used I-beam wooden beam inmainly in the construction of frame-panel buildings. Also, this material often serves as a support for the overlapping of brick, block and monolithic concrete houses. The floors laid on the lags of this species are distinguished by the increased rigidity, they do not creak and never bend.

When erecting the roofs of large-sized buildingsI-beams can be made rafters and skate. This relatively new material can successfully replace the traditionally used for this purpose wooden beams, metal forms, reinforced concrete slabs. Usually the manufacturer gives a guarantee for I-beams on the entire service lines of the building itself.

Advantages of the material

Advantages I-beam wooden beam has a lot. This material is distinguished by such qualities as:

- Strength. I-beams can be installed in very long apertures.

- Stability of form. Such beams do not bend and are not susceptible to shrinkage and deformation.

- Convenience in installation. Processing this building material can be a usual carpenter's tool.

- Versatility. You can use beams with two shelves when erecting floors, ceilings, walls, roofs, etc.

- Ease. The weight of the I-beam made of wood is only 3-4 kg. To raise such an element, for example, the roof does not require special equipment. Only two people will be able to do this.

- Low cost.

Material dimensions

When building buildings, a different I-beam can be used. Its dimensions, most often used in construction, are:

- length - 241, 302, 356, 406 mm,

- Shelf width - 64 mm,

- The thickness of the shelf is 38 mm.

Since this material is often used whenassembly of floors in very wide openings, it sometimes has to be increased. According to SNiP this is allowed. At the junctions of the two beams, locks are fixed. Additional fastening is made on bolts.

In general, building materials are very strong andquality - wooden beams I-beams. GOST, as in the case of the metallic variety, regulates the ratio of the height and dimensions of the elements of this type of supports. You can see them in special tables.

How to make an I-beam at home

If desired, this construction can be made andat home. To do this, you need two bars with a section of at least 35x25 mm. The jumper is made of plywood or OSB. Also need an electric or chainsaw. The work is carried out in the following order:

- First, a furrow with a depth of 10% of the height of the lintel is cut through the length of the uneven bars.

- Then they are cut into lengths of the required length and ground.

- Then glue is applied to the bottom of each furrow.

- The joists are joined in pairs using plywood or OSB.

At the final stage, the finished beam needsput under the press. You can also make it yourself. For this, a channel is used. They are installed above the shelves and pulled together with carabiners or belts.

Manufactured in this way building materialwill cost much less than the purchased I-beam. The price for the latter may fluctuate around 200-250 rubles. Collected independently will cost 1.5-3 times cheaper.

Aluminum I-beams

Building material of this type also hasincreased strength. The I-beam is made of aluminum, usually of the alloy AD31. This variety is most often used in the construction of houses. Also produced aluminum beams from the alloy 1915. This type is distinguished by increased strength. Aluminum beams are stronger than wood and lighter than steel.

Varieties of material

There are aluminum I-beams:

- hardened,

- annealed,

- aged.

The coating of the material can be paint,anodized, powder, electrophoresis, two-layer complex. Under the conditions of application, aluminum I-beams, like steel, can be divided into wide, column and normal. The marking in this case is the same.

Dimensions

An I-beam aluminum beam can alsohave different. Dimensions and in this case are determined by GOST. The marking is also made accordingly. The height of the aluminum beam can vary from 10 to 100 cm. In the first case, the shelf in accordance with GOST will have a width of 55 mm, thickness - 4.5 mm. Determine the ratio of parameters in each specific case can be done by tables.

</ p>