How to make noise isolation with your own hands

Before making soundproofing in yourmachine, you need to determine its purpose. It is made by motorists to get rid of squeaks, to increase the degree of comfort, and also to improve the sound of music in the cabin. And the choice of the material depends on the purpose of noise isolation. If your budget is limited, then you should not undertake the work on the whole machine at once (especially if you are going to do everything yourself). It is much better to do everything in parts, gradually improving your skills.

Tools and materials for work

You will need a certain arsenal of tools to do the work yourself. Here is just an indicative list:

- Hairdryer construction. Use any home, designed for hair styling, it is impossible, because it can not provide the necessary heating.

- Roller cage, with which the soundproofing material is laid and leveled on the surface.

- Large scissors to cut material. It is possible that you will also need a sharp knife.

- White spirit, thinner, kerosene - any of these degreasing agents.

Of course, you may need any tools inprocess of work. Therefore, at hand should be all. Now you should consider all types of noise insulation materials. It is important to know this before making noise isolation with your hands in the car.

Silver and Gold vibroplast

Elastic, flexible, vibration-absorbing material. It is a self-adhesive material with an aluminum foil on the outside. On it there is a marking in the form of squares of 5x5 cm. Due to this layout it is possible to cut large sheets into elements of the necessary size and shape.

This material is waterproof,external factors does not decompose, performs the functions of anticorrosion and sealant. Its installation is easy, regardless of the terrain. Heating of the surface is not necessary, without defects it is laid on the cold elements of the car body. Weight of sound insulation is not more than 3 kg / sq. m, the thickness is stable 2 mm. The loss factor (mechanical) in the interval 0.25 ... 0.35.

It is possible to trim such material with doors, roofs,body sides, floors in the cabin, a shield separating from the engine compartment, bonnet and boot lid. Vibroplast type "Gold" is very similar to the one described above, but there are differences. The square meter of material has a mass per kilogram more, since the thickness is 2.3 mm. The mechanical losses are about 0.33. Since this material is thicker, then the quality of noise insulation is better, all extraneous sounds disappear.

Bomb Bi-Mast

This material is also vibration-damping. The multilayer structure consists of several layers, the outer one - aluminum foil. Bitumen and rubber compositions - the second and third layers. When you are installing this material, it is necessary to heat the surface to a temperature of at least 40 degrees (more efficiently - up to 50). Since it is impossible to make the noise isolation of the car with your own hands without heating, you need a good hair dryer.

"Bi-Mast" does not absorb moisture, it is consideredthe best vibration isolation material to date. He has the highest efficiency. It is worth noting that the loss factor is about 0.5! But the mass of the material is rather big - 6 kg / sq. M. m, thickness - 4,2 mm. Ideal for audio speaker training. They are processed wheel arches, the zones above the propeller shaft and silencer, the shield between the cabin and engine compartment.

"Splen" 3004, 3008, 3002

Soundproof material on which is appliedglutinous composition. Its special feature is high thermal insulation qualities. Easy installation on curvilinear and vertical surfaces. It is waterproof, does not decompose under aggressive media, and weighs less than 0.5 kg / sq. m., with a thickness of 4 mm. The operating temperature is in the range -40 ... + 70 degrees. This material is treated with a shield between the cabin and the engine compartment, wheel arches, tunnels, doors. Before correctly making soundproofing, you need to study all kinds of materials.

On sale you can also meet "Splen" withindex 3008, which has a thickness of 8 mm, as well as 3002 - it has 2 mm. As you can see, the last figure is the thickness of the material. This material is pasted after vibration isolation (discussed above). To ensure that the joints are strong, it is necessary to clean and degrease the surfaces. The optimum surface temperature is in the range of 18..35 degrees. If lower, the material properties are lost. Pay attention that the application of "Splen" should be made without tension, as it can damage it.

Anti-scratch "Bitoplast"

To get rid of creaks, rattling in the cabin,this noise absorbing material is used. It is based on polyurethane foam, there is also an adhesive layer and a protected release liner. Waterproof, durable, not prone to rotting and decomposition, soundproofing, also has the properties of a heat insulator. And does not lose its properties, even in the extreme north. At a thickness of 0.5 cm, the mass of the material is only 0.4 kg / sq. There is a variety and twice as thick (10 mm), called "Bitoplast-10". This material makes noise isolation of the car is not difficult. And a big plus - get a thermal insulation.

Accent-10

"Accent-10" consists of a film with the addition ofmetals, which is on elastic polyurethane foam. The latter is covered with a sticky layer. Waterproof and not subject to decomposition, this material is also used as a heat insulator. As a rule, it is used as a sound-absorbing material and heat-insulating material. Can absorb about 90% of noise. The thickness is only 10 mm, and the mass is no more than 0.5 kg / sq. m. Operating temperature ranges from -40 .. + 100 degrees. Processed with the help of "Accent-10" trunk lid and bonnet, as well as a partition between the cabin and the engine compartment.

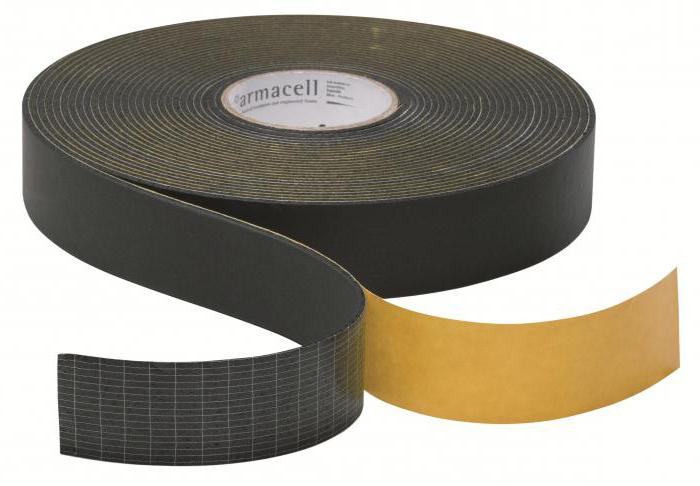

Madeline

Serves for compaction, but is often used inAs a decorative material, because it is based on a black fabric. Thickness - no more than one and a half millimeters, on the one hand - adhesive composition, as well as protection from adhesion. It is applied for processing of backlashes in decorative elements of a body and salon, the instrument panel, air ducts. It is worth noting that these materials are the most common, their quality is at a high level. But on sale you can find similar products from different manufacturers. And the price at them can differ essentially. Of course, practice shows that at a low price, you get the same quality. But if you have wondered how to make noise isolation from neighbors (in the yard, in the case of a metal fence), then you can choose any available material.

Carrying out of works on noise isolation of the hood

Please note that after thenoise insulation of the hood you will not get rid of the sound of the engine. It is done only in order to keep warm in winter. Insulation of the hood is done with the help of "Vibroplast" and "Accent", discussed above. The most important thing is to take into account the bulk of the material. If it is too big, it will affect the work of the front suspension. It is clear that the harsher the winter, the thicker the layer is desirable to do. But, on the other hand, do not forget about the "native" insulation. It should not be thrown out, it will be best if the new one acts as an aid to what is already available.

Sound insulation of car doors

Here it is getting rid of strangersnoise, which are heard when the car moves. But it's still not superfluous to say that the front speakers located in the doors sound much nicer with high-quality noise insulation. It will be enough to lay one material - "Vibroplast" or its analogues. The amount of the total material depends directly on the area of the coating and the thickness of the metal. But you do not need to heavily weight the door - the hinges will start to sag and the locks will collapse. Here's how to make the car door soundproofing. The main thing is to withstand the norm, do not overdo it and do less.

</ p>